pushed forwards with the push block.

• Chamfering or bevelling: The work piece is

positioned against the jointing fence. Set

the guard rail of the cutterblock cover to the

width of the work piece and place it on the

table. The work piece is pressed against the

fence and the unloading table with the left

hand, fist closed, and pushed forwards with

the closed right hand.

• Warning! Never work with a jointer without

the cutterblock cover.

Electric connection

m

• Check the mains connection cables. Do not

use faulty cables. See Electric connection.

• Observe the rotational direction of the motor

and the tools, see Electric connection planer.

• Installations, repairs and maintenance on the

electric installation may be carried out only

by experts.

• Turn the machine off when resolving issues.

Disconnect the mains plug.

• Turn the motor off when you leave the work

place. Disconnect the mains plug.

• Disconnect the machine from every external

energy supply even for slight changes of

position! Connect the machine to the mains

again before using it!

Connect the machine to the mains with a

CEE-plug, the supply line has to be protected

with 16 A.

On the operating switch, press the green push

button, the cutterblock starts up (fig. 14).

To turn it off, press the red push button, the

cutterblock stops within 10 sec.

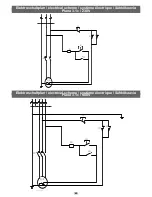

Change of rotational direction

When connecting the machine to the mains or

changing its position, the rotational direction

has to be checked. The polarity has to be

swapped, if applicable, using a screw driver

(machine socket fig. 15).

The installed electric motor is connected and

operational. The connection complies with

relevant VDE and DIN stipulations. The mains

connection at the customer’s as well as the

extension lead used have to comply with these

stipulations or the local EVU-stipulations.

Duration of use / duty cycle

The electric motor is for operating type S1 for

continuous operation.

When there is an overload, the motor turns

itself off because a winding thermostat is

integrated in the motor development. After a

cool-down period (timing varies), the motor

can be turned on again.

Hazardous electric connections

Insulation damage often occurs on electric

connections.

Possible causes:

• Pressure marks when connections are gui-

ded through windows and doors

• Kinks due to inappropriate attachment or

guidance of the connection

• Cuts when the connection is run over

• Insulation damage when being pulled out of

the wall socket

• Tears from ageing insulation. Such hazar-

dous electric connections must not be used

and are dangerous to life due to the insulati-

on damage.

Regularly check electric connections for

damage. Make sure the connection is not con-

nected to the mains when checking. Electric

connections must comply with relevant VDE

and DIN stipulations and the local EVE stipula-

tions. Only use connections marked H 07 RN.

Printing the type designation on the connec-

tion is the law.

Extension leads up to 25 m in length must

have a cross section of 1.5 mm2, at more than

25 m length, it has to be at least 2.5 mm2.

The mains connection is protected against

short circuit with a 16 A slow fuse.

Three-phase motor

The power voltage has to be 380÷420 V 50

Hz.

Mains connection and extension leads have to

be 5 core =3 P + N + SL.

Extension leads must have a minimum cross

section of 1.5 mm².

The mains connection is protected against

short circuit at a maximum of 16 A.

When connecting the machine to the mains or

changing its position, the rotational direction

has to be checked. The polarity has to be

swapped, if applicable, using a screw driver

(machine socket fig. 15).

One-phase motor

The power voltage has to be 230 V 50 Hz.

Connections and repairs to the electrical

equipment may be carried out only by a trai-

ned electrician.

If there are any questions, please provide the

following data:

• Motor manufacturer; motor type

• Motor’s type of power

• Data from the machine’s type plate

• Data from the electronic control

When sending back the motor, always send

the entire motor unit with electronic control.

Maintenance

m

WARNING

Before working on the power tool itself (e.g. transport, set-up, re-tooling, cleaning and maintenance), disconnect the mains

plug from the socket!

■

CLEANING

Carry out maintenance, service and repairs

as well as malfunctions only when the motor

is turned off. Turn the machine off via the off-

switch, then disconnect the mains plug!

All protective and safety equipment must be

re-attached immediately after completing

repairs and maintenance.

Always keep the jointer tables and the thick-

nessing table free from resin. The bearings

of the cutterblock are permanently lubricated.

Warmth occurring when the machine is in a

new condition is due to construction and will

disappear with time.

Clean the feed rollers regularly.

After the first 5 operating hours, oil the plain

bearings of the feed rollers, the adjustment

spindle of the thicknessing table, their bea-

rings. Repeat every 20 operating hours with

further use.

Planing knives

The HSS planing knives inserted in the factory

are operational and set up correctly.

Only well-sharpened and correctly set-up

planing knives guarantee safe work.

We recommend: Always keep a second set of

new planing knives ready for replacement.

Replacement planing knives are available

from your stockist.

Inserting planing knives fig. 16

1 Setting screw

2 Pressure screw

3 Planing knives

4 V-ledge

When inserting, be aware that

• there is a risk of injury to fingers and hands.

• the clamping areas in the cutter and the v-

ledges are cleaned.

• the sharpened planing knives are oiled.

• only knives re-sharpened in sets are used.

• inserting the planing knives and v-ledges is

carried out according to the figure.

• the planing knives, knife supports and v-

ledges are flush with the cutter on both sides.

• the clamping screws are tightened (8.9 N/m).

Warning!

The details concerning knife attachment, knife

protrusion, knife width, min. clamping length

and ideal tightening torque of the knife moun-

ting screws have to be complied with exactly.

GB

20

Summary of Contents for plana 3.1c

Page 4: ...1 1 3 4 2 6 5 12 10 8 9 13 7 11 4...

Page 5: ...2 2 5 3 3 1 A B C 3 4 5 2 1 6 2 1 7 5 6 D 8 D 5...

Page 6: ...9 9 1 9 2 10 11 12 12 1 13 12 9 E 8 7 K L M F G 10 11 D 6...

Page 23: ......

Page 25: ......