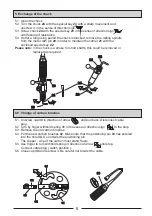

2.4 The milling spindle holder can be fixed in any desired postion by turning knurled

knob

. At the top side of the milling spindle holder there are two grip sleeves

for depth stop and for tension of the spring.

The tension of spring can be adjusted in each position between the upper and the

lowest fix point. The spindle or depth stop

shows a radial graduation of

50 x 0,01 mm and an axial graduation of 0,5 mm.

One complete rotation of this spindle is 0,5 mm. The complete vertical way of the

milling spindle holder is 20 mm. If drill-lever

is not used, it can be screwd out

and be placed in the boring at the backside of the main arm.

2.5 To pull milling spindle out knurled screw

has to be loosened. When putting

milling spindle please push spindle until it reaches the stop point. Lever

- which

is used ot open and to close the chuck - has to be in the left position with closed

chuck. Then fasten knurled screw

again.

The surveying spindle

- delivered as accessory - can be put into milling spindle

holder in the same way. If not used the surveying spindle is placed in the boring

at the rear side of the arm.

3.1 After a long period of use it is possible that the model table

is not longer strong

enough. This can be corrected by turning the set screw at the bottom side of the

model talbe.

To open the chuck turn lever

right until it stops. Then you can pull out

the tool. After the new tool is placed in the chuck turn lever

left until it stops.

Considering precision and life time of the chuck, be sure that a tool is always -

even when the machine is not in operation - firmly mounted in the chuck

(13)

(16)

(14)

(11)

(12)

(11)

(19)

(15)

3. Swivelling model table

(18)

4. Exchange of tools

(12)

(12)

ATTENTION: Exchange of tools only when motor is stopped !.

3

12