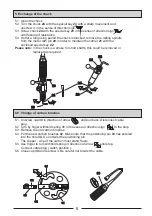

5. Exchange of the chuck

24

23

24

23

20

21

22

Pease note:

6.0 Change of carbon brushes

30

31

32

33

34

30

5.1 Open the chuck

5.2 Turn the chuck

with the special key

with a sharp movement and

unscrew it, in the sense of direction sign.

5.3 Screw chuck

with the special key

in the sense of direction sign

until feeling of resistance.

5.4 If after a long using period the chuck is blocked, remove the milling spindle

from the motor with pin

in order to maintain the carrier

with the

enclosed special key

.

In the chuck is a stroke for short shafts, this could be removed or

replaced as required.

6.1 Unscrew cap

in direction of arrow and pull back. Disconnect cable

plug.

6.2 Turn by finger withhold spring

in the sense of direction sign to the stop

6.3 Remove the old carbon brushes

6.4 Put the new carbon brushes

. Make sure that the positioning pin

has entered

into the hole

. Do not twist the positioning pin.

The copper - wire of the carbon must stand freely.

6.5 Use finger to turn withhold spring in direction of arrow until stop.

Connect cable plug ( watch position ).

6.6 Close cap

and rescrew it. Be careful not to twist the cable.

5

20

23

24

21

22

23

24

30

31

31

32

33

34