Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

7 Commissioning

7.2.5

Required torque on the handwheel

The following table shows the maximum torque applied to the handwheel for the different actuator sizes.

Type

Max. handwheel torque

[

Nm

]

Handwheel

diameter

[

mm

]

In Failsafe direction

Counter Failsafe

direction

CM03F(S)QT30

4

8,5

140

CM03F(S)QT60

4

14,5

140

CM06F(S)QT100

8

32

200

CM06F(S)QT200

8

28,5

200

CM06F(S)QT300

8

31

200

CM06F(S)QT500

8

32

200

The force on the handwheel was calculated for one-handed operation. With two-hand operation, the value per hand is

halved. The maximum force may be exceeded by 20% in manual mode.

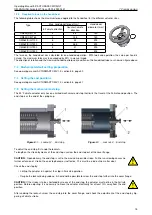

The direction of rotation and the maximum handwheel torque are written on the handwheel label, as shown on figure above.

7.3

Mechanical default setting, preparation

See operating manual ACTUSMART CM.V1.2, section 5.3, page 30

7.4

Setting the end positions

See operating manual ACTUSMART CM.V1.2, section 5.5, page 31

7.5

Setting the mechanical end stop

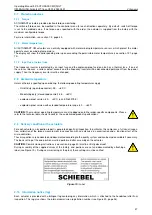

The 90° Failsafe actuator only has one limited mechanical end stop that limits the travel at the Failsafe end position. The

end stop is at the end of the spring cup.

Figure 8:

1. . . Locknut, 2. . . End stop

Figure 9:

1. . . Locknut, 2. . . End stop

To adjust the end stop, first undo the locknuts.

To lengthen the stroke by means of the end stop, unscrew the end stop out of the cover flange.

CAUTION:

Upon delivery, the end stop is set to the maximum possible stroke. Further unscrewing causes no

further extension of stroke; the end stop becomes ineffective. This must be ruled out no matter what.

Check the end stop by:

• Letting the actuator run against the stop in Failsafe operation.

• Despite the locknut being undone, it should not be possible to screw the end stop further into the cover flange.

CAUTION:

If the stroke is to be shortened by means of the end stop, the actuator must not be in the Failsafe

position. Before adjusting, it is necessary to move the actuator electrically for at least 10% away from the end

position.

After undoing the locknut, screw the end stop into the cover flange, and check the adjustment of the end stop by trig-

gering a Failsafe stroke.

15