10 Technical data Failsafe brake

Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

10

Technical data Failsafe brake

10.0.1

CM03F(S)QT

Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 W

Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 V

Current: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,67 A

10.0.2

CM06F(S)QT

Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 W

Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 V

Current: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,875 A

10.0.3

CM12F(S)QT

Power: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 W

Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 V

Current: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,17 A

11

Spare parts

When ordering spare parts, let us know the serial number of the actuator.

A separate exploded diagram and a spare parts list is available for selecting spare parts.

12

Lubricant recommendation / Lubricant requirements

See operating manual ACTUSMART CM.V1.2, section 15, page 76

12.1

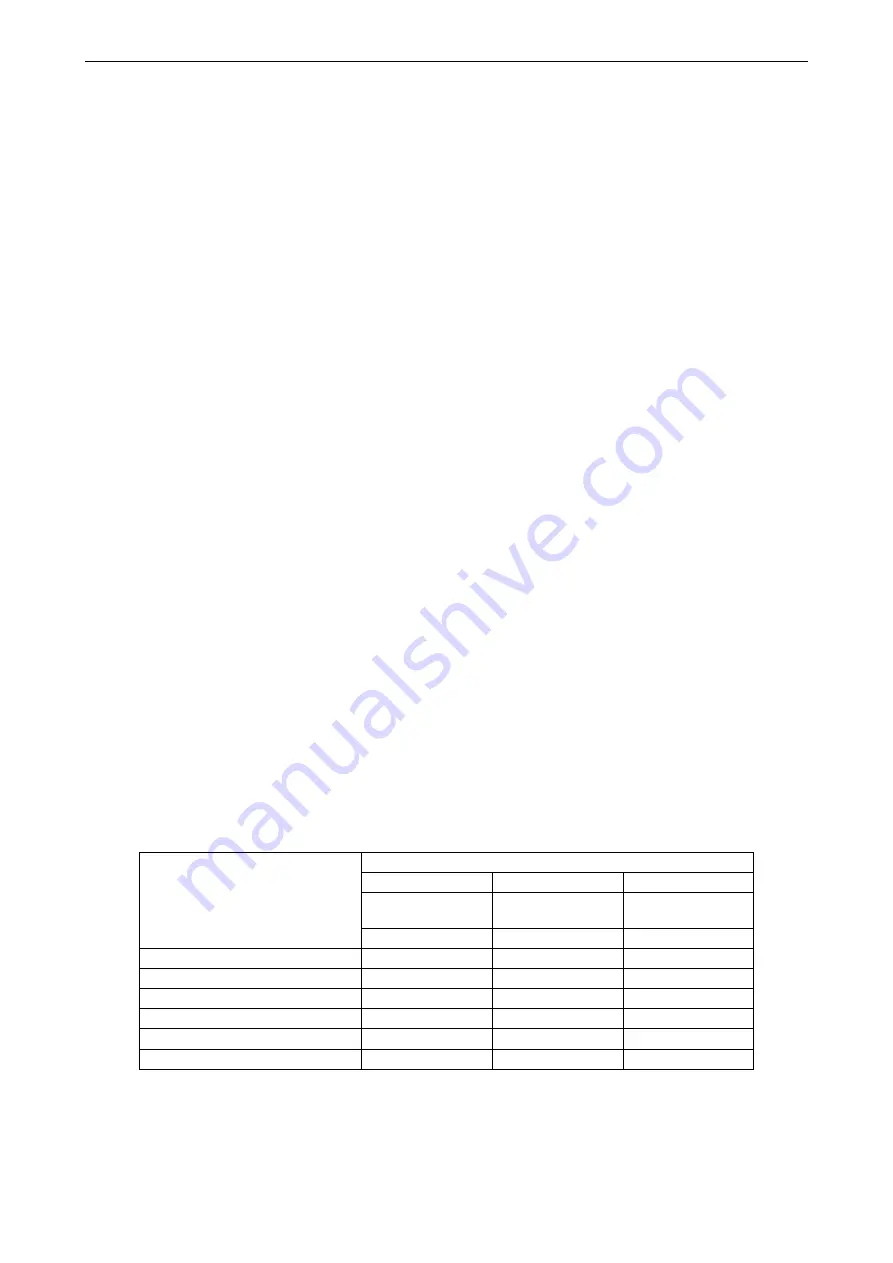

Lubricant points F(S)QT

The table values given apply to relubrication in accordance with the relubrication intervals in the operating instructions.

After relubrication has been carried out, 2-3 full strokes must be performed. If torque switch off occur, the grease nipples

must be removed and the strokes repeated.

NOTE:

Lubricant can leak out of the lubrication points.

The grease nipples should be reinstalled, in case of removal.

The spindle nut is or should be lubricated during initial assembly or after complete disassembly, including all gears and

bearings. Also, all moving parts as well as internal surfaces are coated to cover them.

→

Lubricant quantity according to expenditure

→

Lubricant specification according to the operating instructions depending on the temperature range

Type

Lubrication point

[

Quantity

]

1

2

3

Main gear

Bearing spindle

drive

Intermediate gear

[

cm

3

]

[

cm

3

]

[

cm

3

]

CM03F(S)QT30

8

-

-

CM03F(S)QT60

18

-

-

CM06F(S)QT100

20

42

-

CM06F(S)QT200

20

68

29

CM06F(S)QT300

20

90

59

CM06F(S)QT500

20

80

90

20