4 Installation instructions

Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

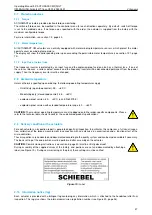

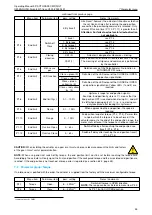

Thread

Tightening [Nm] for screws with strength class

8.8

A2-70 / A4-70

M6

11

8

M8

25

18

M10

51

36

M12

87

61

M16

214

150

M20

431

294

M30

1489

564

NOTE:

For output type A (unbored threaded bushing), you must sufficiently lubricate both needle bearings in the output

form after processing and cleaning the spindle nut.

For this purpose, use the optional SCHIEBEL grease lubricant or a grease lubricant according to our recommendation

(see section 15.3, page 77).

4.2

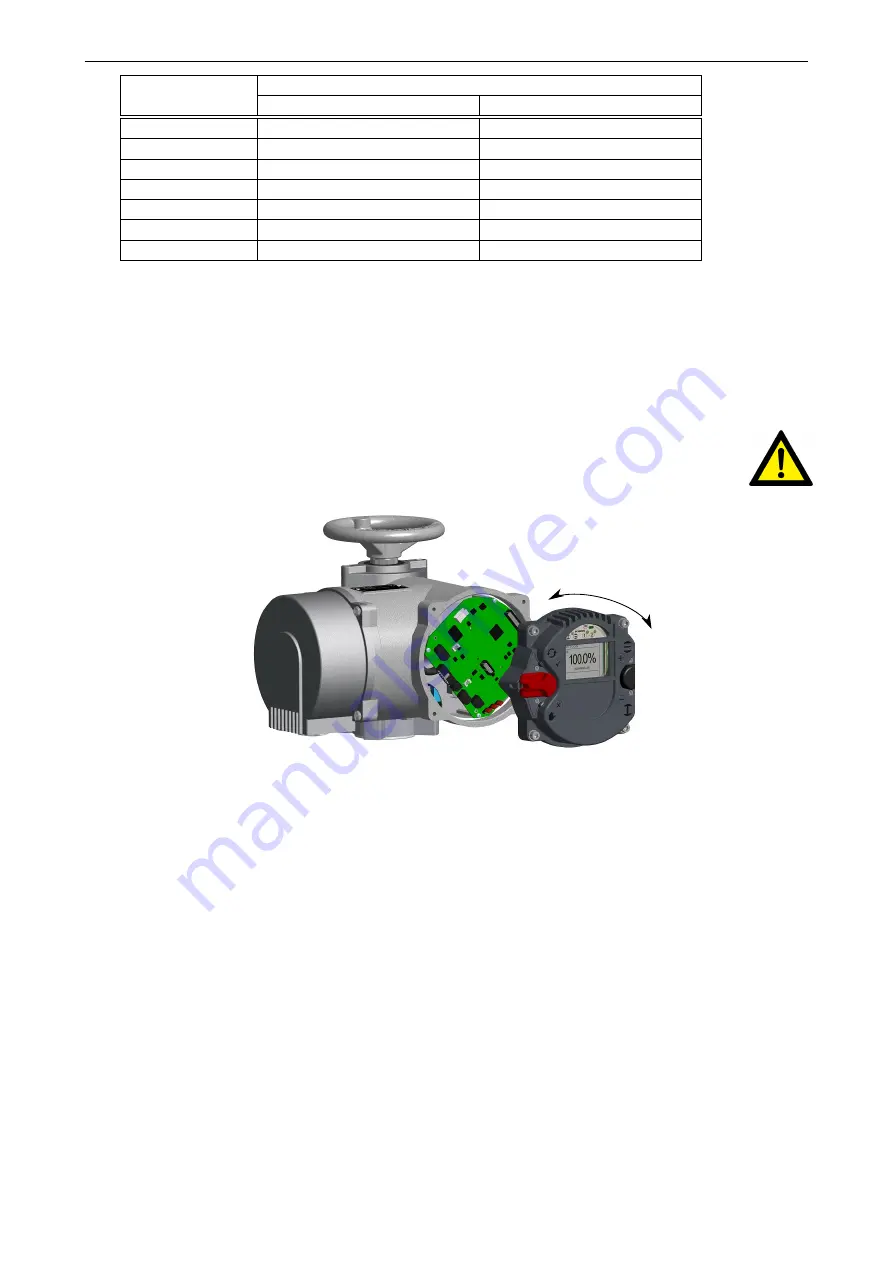

Mounting postion of the operating unit

The mounting postion of the operating unit can be rotated in 90° steps.

CAUTION:

During installation, the position of the control unit in relation to direct sunlight must be observed. It is

recommended to protect the unit from direct sunlight (roof, installation position) to avoid possible malfunctions.

-90°

+90°

+180°

Figure 22

• Disconnect the actuator and control system from the power supply.

• To prevent damage to the electronic components, both the control system and the person have to be earthed!

• Unscrew the bolts for the interface surface and carefully remove the service cover.

• Turn service cover to new position and put back on.

–

Ensure correct position of the O-ring.

–

Turn service cover by max. of 180°.

–

Put service cover on carefully so that no cables get wedged in.

• Screw the bolts shut evenly in a crosswise sequence.

IMPORTANT:

max. torque 5 Nm

30