Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

11 Maintenance

11

Maintenance

WARNING: Maintenance work on open actuators may only be conducted if these are de-energized. Re-

connection during maintenance is strictly prohibited. Work on the electrical system or equipment must

be carried out only in accordance with electrical regulations by a qualified electrician himself or by

specially instructed personnel under the control and supervision of a qualified electrician.

WARNING: For explosion-proof actuators, it is necessary to wait a certain time after switching off be-

fore opening the cover; see explosion protection sticker (Picture 86).

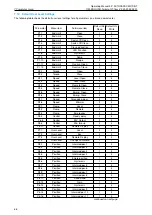

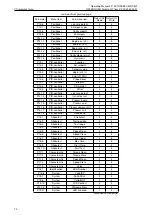

Following times are specified for the actuators.

• CM03: 5 min

• CM06: 10 min

• CM12: 15 min

1

Figure 86:

1. . . Explosion protection sticker

Actuators are ready for use after installation. By default, the actuator is delivered filled with oil.

On-going monitoring:

• Beware of increased running noise. During long downtime periods, operate the actuator at least every 3 months.

• For actuators with output types A, B and C according to DIN 3210-A, B1, B2 and C according to DIN ISO 5210,

re-lubricate at least every 6 months on existing grease fittings (see section 15.3, page 77).

Actuators are designed for installation in any position (see section 2.5, page 24). Therefore, the main body is not equipped

with a level indication or a drain plug.

The replacement of the lubricant from the main body must be performed via the handwheel.

Every approx. 10,000 to 20,000 hours (about 5 years, see section 15, page 76), depending on the workload, you must:

• change oil, and

• replace seals.

Check all roller bearings and the worm-wheel assembly and replace if necessary.

Check our lubricants table for recommended oils and greases (see section 15, page 76).

NOTE:

Check the cable glands at regular intervals (annually) for tightness of the cables and retighten if necessary.

If the visual inspection (eg. dust or water penetration) indicates that the effectiveness of the sealing elements of the cable

entry has suffered damage or aging, such elements have to be replaced preferably by using the original spare parts from

75