Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

5 Commisioning

1

Figure 35:

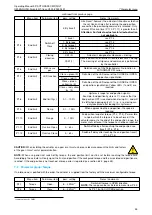

1. . . Absolute value

When the desired end position OPEN of the valve is reached, move the selector switch back to the middle position. Thus,

the line "TEACHIN" disappears.

Figure 36

Figure 37

In order to confirm the end position (save), slightly flip up the selector switch towards

and let it snap back to its neutral

position.

Figure 38

⇒

Figure 39

⇒

Figure 40

This changes the bottom line of the display for "SAVE?" to "EDIT?" and the end position is stored.

Figure 41

Figure 42

5.5.2

End limit CLOSE

Use menu item "P 1.2 End limit - End limit CLOSE" as for End limit OPEN

35