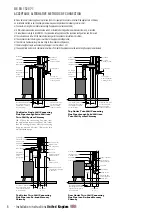

CONNECTING FLUE PIPE

Appliance/Chimney Connection

Connection to the appliance can be made using approved single wall connecting flue pipes�

This must be done by using the appropriate appliance connector� When a single wall connecting flue pipe is used to connect an appliance to the chimney, the lower end of the

chimney section must extend a minimum of 425mm below the ceiling� When connecting the appliance to the flue pipe all joints between the flue pipe/appliance outlet must be

securely caulked and sealed with non asbestos rope (or suitable alternative) and fire cement on solid fuel appliances�

Any flue pipe connection to the chimney MUST be made in the same room as the appliance�

Connection to Draught Diverter

Where the appliance features a draught diverter the connection should rise vertically from it for at least 600mm before any change of direction (unless otherwise specified by

the appliance manufacturer)� This is in accordance with the recommendations contained in BS 5440 Part 1 section 6�1�4

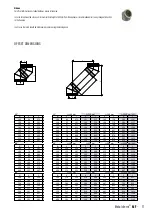

Connecting Flue Pipe Diameter

Connecting Flue Pipe Diameter size should be as recommended by the appliance manufacturer� Under all circumstances the operational requirements of the appliance and the

configuration of the flue must satisfy the flue sizing requirements of EN13384-1�

Distance to Combustibles

In accordance with building regulations, it is essential that the correct distance to combustible material is maintained on connecting flue pipes� On solid fuel applications,

where there is a risk of soot fire, on unmeasured (NM) designated single wall product, this distance is 3 x ØInt of the pipe, e�g� for Ø125mm the distance is 375mm and for

Ø150mm the distance is 450mm to combustibles on both painted and non painted variants� On measured (M) single wall or double wall products this distance will be as

declared by the chimney manufacturer�

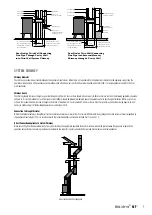

Connecting Flue Pipe Route

Single wall connecting flue pipes should only be used to connect appliances to a Chimney� They should not pass through any roof space, partition, internal wall or floor, except to

pass directly into a chimney through a wall of the chimney�

Connecting flue pipes should be located as to avoid igniting combustible material�

On solid fuel appliances the maximum length of a connecting flue pipe is 2m� This distance is reduced to 1�5m if any of the acceptable alternative methods of connection are

adopted as per BS EN15287-1� (See p�5-6 for full details�)

On appliances with a top outlet, it is recommended that a vertical run of at least 600mm should be allowed immediately above the appliance prior to any change of direction�

On appliances with a rear outlet, it is recommended that there is maximum of 150mm in the horizontal run however under certain conditions, as described in alternative

methods in BS EN 15287-1, this may be increased to 450mm� (See p�5-6 for full details�)

Within a system (C Connecting Flue Pipe) there should be no more than 4 changes of direction of maximum 45˚�

90˚ Factory made bends or tees within the system may be treated as being equal to two 45˚ bends (as per Document J of the Building Regulations issued October 2010)�

Inspection

On solid fuel applications to conform to Building Regulations, provisions should be made to enable a chimney to be inspected and cleaned�

An inspection pipe, inspection elbow or a 45° or 90° Tee with tee cap can form a suitable inspection point (unless cleaning/inspection can be done through the appliance)� To

aid cleaning, sufficient distance should be left between changes of direction to permit the safe passage of cleaning brushes within the system� This is particularly important on

solid fuel applications� It is recommended that chimneys serving solid fuel appliances be swept as frequently as necessary, but at least twice a year�

5

Metaloterm

®

MF

-