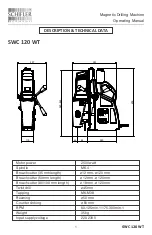

5.1 How to mount tools or adapters in a Weldon arbor?

1) Make sure the machine is disconnected from the power supply.

2) Put the center pilot in the cutter hole.

4) Tighten the retaining screws.

5) Check if the center pilot can move inside the cutter (up and down).

5.2 Drilling with Core Drills

3) Put the cutter or adapter in the arbor, making sure the flat sides are

exactly in front of the arbor retaining screws.

2 Switch on the magnet.

1 Place the machine at the desired position

3 Ensure that the magnetic drilling unit is secure on the working piece.

4 Fill the arbor with lubrication/cutting oil in the special meant holes. Always

use cutting oil from your dealer.

CAUTION :

For 100% magnet clamping force you need at least 10 mm of steel.

Coatings, paintings and dirt between magnet and workpiece will affect clamping

force.

5 Start the motor by pressing the green motor start button (I).

Magnetic Drilling Machine

Operating Manual

OPERATING MANUAL

3

7

SWC 120 WT

10