Magnetic Drilling Machine

Operating Manual

of the power cord and the plug. Replace them immediately if you see any

damage.

8. Do not overload the motor for than a total duration of 30 minutes. If done

otherwise, it will lead to extreme heat getting generated that will result in

a fire or explosion. Switch off the motor when it is not in use.

5. Don't press the drill machine too hard as that may lead to an overload,

which tends to shorten the life of the magnetic drill. When in use, be

extremely attentive to the condition of the magnetic absorption of the

drill. Stop using the drill immediately if you notice any instability in the

magnetic absorption.

3. Study this manual well to understand the Do's and Don'ts of the Drilling

tools. They should be used strictly according to the size specified. The

material of the drilling workpiece comes with a magnetized absorption

and works better on a smooth surface. Double check that its thickness

ranges between 10mm-75mm, without the 0.5mm thickness of Iron

scrap and the presence of paint, granular impurities and any other

foreign particles should be avoided.

7. Do not continuously operate the magnetic base with a full load as that

will cast a strong effect negatively on the life of the magnetic base. It may

also get heated up to an extent that it may catch fire. Never touch the

magnetic base, especially when it is extremely hot as that will cause a

serious burn. Turn off the switch and unplug immediately once you stop

using the magnetic base.

4. If the thickness of the drilling machine is less than 10mm, you must

ensure that it is well-supported by iron plates right at the bottom that

come with a thickness higher than 10mm. The supporting iron plate must

have a base area greater than the drilling machine's area of the magnetic

base if you need to improvise the reliability of the capability of the

magnetic base's absorption. In case you opt for a supporting iron plate

which is thinner than the requirement, you will notice the drilling

machine becoming lose in the process of absorption that may lead to

unwanted and fatal accidents.

2. The power supply should always be in sync with what the equipment

requires. Hence, ensure the same while making sure that safety

measures for grounding and leakage are made available.

6. Whenever the drill starts to operate or shuts down, ensure that the

operating sequence of the motor and magnetic switch has been

complied.

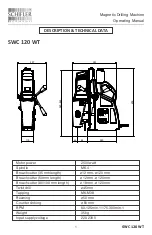

SWC 120 WT

6