Magnetic Drilling Machine

Operating Manual

6 Start bringing the cutter to the workpiece but handle with care and do not

apply too much pressure. The cutter has to find its way in to the material by

itself. After 2 mm, the groove of the cut will help the cutter maintain its place

and you can increase the power. Still it is not necessary to use a lot of

pressure. Too much pressure will cause damage and breakage.

7 After the cut is finished the slug will automatically be ejected from the cutter,

switch the machine off by pushing the red button(0).

WARNING: THE SLUG WILL BE EJECTED AND IS VERY HOT

2 Switch on the magnet

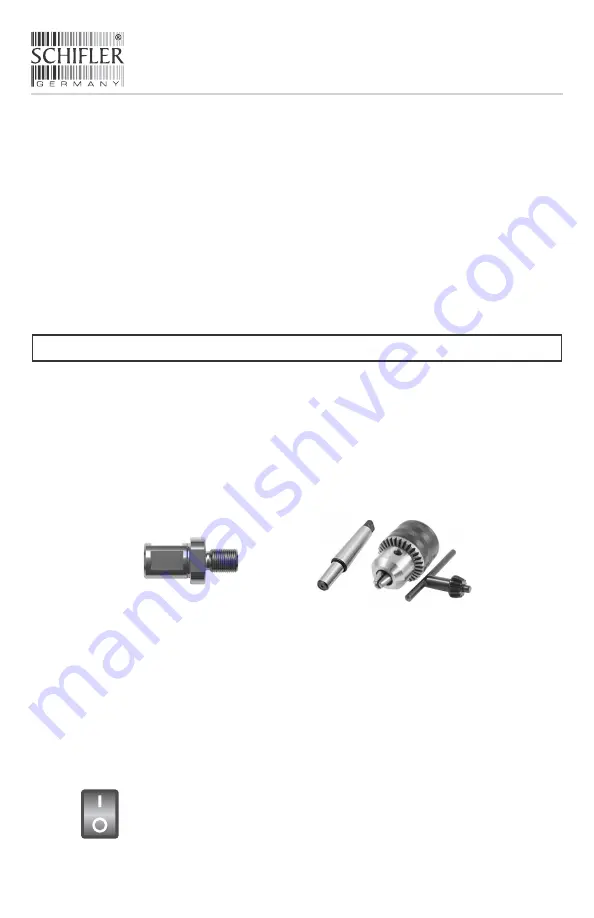

- Adapter 19 mm Weldon - ½”x20 UNF

1 Place the machine at the desired position

- Adapter 19 mm Weldon – B16 taper connection

8 If the slug gets stuck in the cutter, move the machine to a flat surface. Switch

on the magnet and gently bring the cutter down in contact with the surface.

This usually allows a slug to straighten and to eject.

- Adapter 19 mm Weldon – B18 taper connection

There are several accessories available to be able to use twist drills with your

magnetic drill.

These adapters will allow you to attach a drill chuck on to the hole cutter arbor.

(ranging from Ø 6 – Ø 12 mm)

Also twist drills with a direct Weldon connection are available

5.3 Drilling with twist drills

11

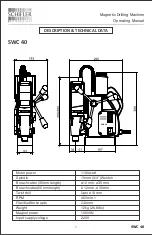

SWC 40

Drill Chuck

Weldon Drill Chuck Adaptor

Summary of Contents for SWC 40

Page 1: ...Magnetic Drilling Machine OPERATING MANUAL SWC 40 SWC 40 ...

Page 15: ...Magnetic Drilling Machine Exploded View SWC 40 Motor complete Antriebseinheit 13 SWC 40 ...

Page 22: ...NOTES Magnetic Drilling Machine Operating Manual SWC 40 SWC 40 ...

Page 23: ...NOTES Magnetic Drilling Machine Operating Manual SWC 40 ...