automatic cable rewinder FT 260/350 - EFT 265 MFK

installation and operating instruction

installation and operating instruction FT 260_350-EFT 265 MFK - A5

page 3

01.04.2021

Schill GmbH & Co. KG; Bruckstraße 44; 70734 Fellbach

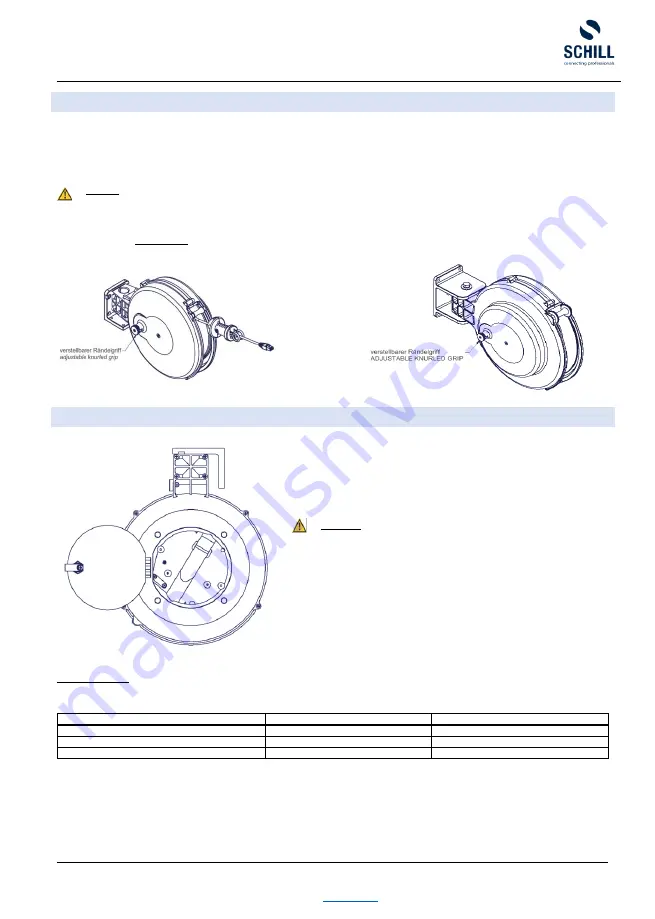

LOCKING DEVICE

As a standard feature the cable reel has a disengageable cable locking device. The latching mechanism ensures that the pulled-out cable

stays without traction fixed in place. When the cable is being pulled out, the spring detent passes over a series of grooves. An audible

click indicates that the locking device is engaged. If you gently rewind the cable after the clicking sound, you will notice that the spring

detent will engage into the notches, locking the cable in position. The cable can be disengaged by gently continuing to pull the cable until

the click can no longer be heard. The tensioned spring will pull the cable back onto the reel.

Attention

Do not release the cable when rewinding, the tension of the spring can accelerate the winding speed to such a degree that the

swinging cable end could cause injury. Also damage to the cable and spring could be the result of such an action.

The locking device

FT / FTE 260

can be disengaged by pulling the knurled grip out by approx. 1cm and turning it between 90° and

180°. This will disengage the locking device the cable is then constantly under tension.

CABLE ASSEMBLY

The standard MFK cable reels are supplied as standard without cable

assembly (see "Installation Cables".

The cable is installed in the cable reel in such a way that a cable with the

connection length X protrudes on the connection side. Cable assembly is

described below. To change the extension length, the connection cable must

be rolled up in the coil and fastened.

Attention

When rolling up and unrolling, the connecting cable must be stored

inside the coil and secured with the Velcro fastener. Otherwise, the line

may be damaged and there is a risk of injury due to the swirling end of

the connection cable.

The maximum pull-out length depends on cable outer diameter (OD), cable

weight incl. plug-in device, weight of the cable stopper

and the built-in coil

spring.

FT 260 - EFT 265

Starting from a standard spring, with a maximum of 24 revolutions, the following pull-out and connection lengths are possible.

cable OD [mm]

pull-out length [m]

connection length [m]

≤ 8

10

1,5

≤ 10

8

1,2

≤ 12

6

0,9

The maximum spring force is 30N (3kg).