1

1

TRUCKLOADER

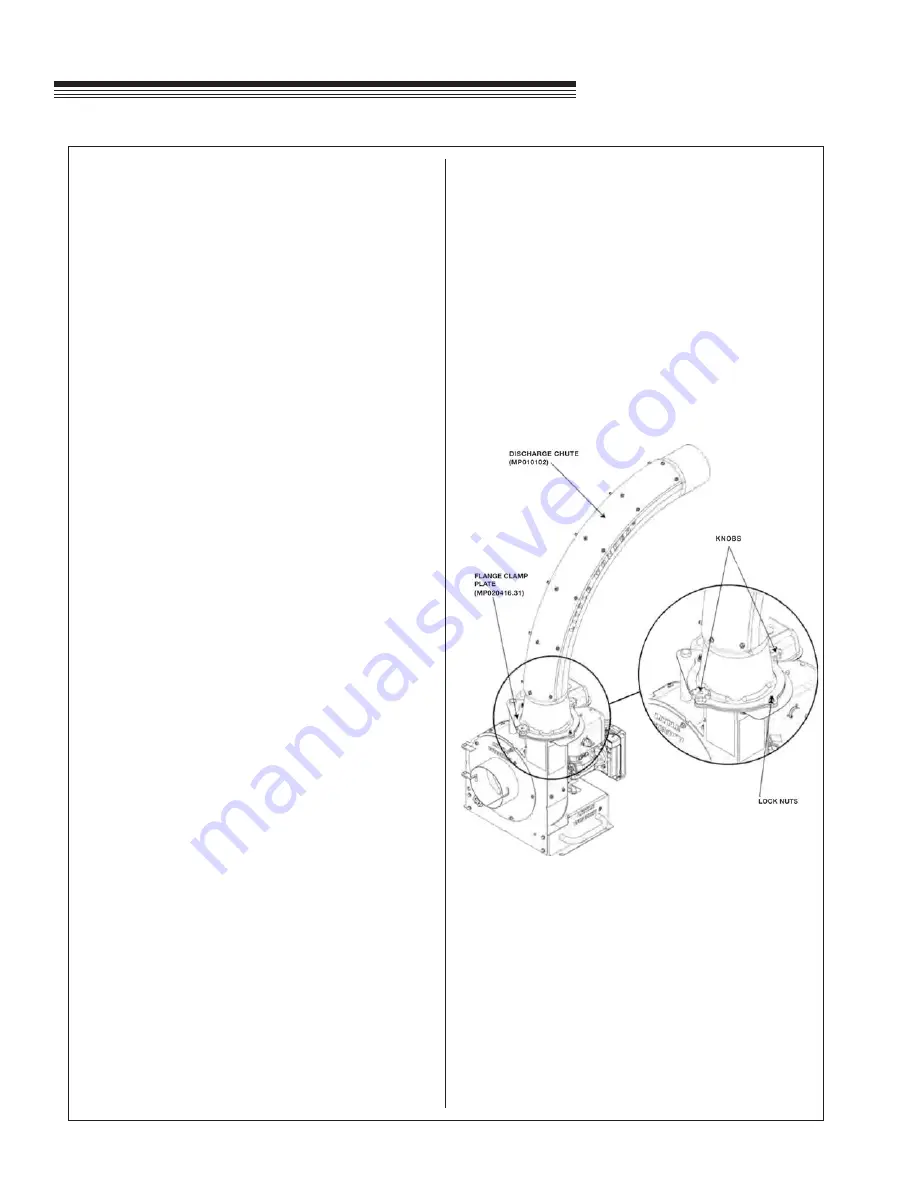

SET UP INSTRUCTIONS

INSTALL DISCHARGE CHUTE TO POWER UNIT

1. Slide the flange clamp plate over the discharge

chute deflector down to the flange.

2. Orient the discharge chute with liner so its flange is

facing the top of the Shredding truckloader housing,

and slide the flange clamp plate over the four

housing flange studs.

3. Direct discharge into The debris receptacle, and

affix it with (2) two knobs, (2) two flanged nylon

insert nuts as shown below.

CHANGE DISCHARGE CHUTE DIRECTION

1. Loosen knobs and nuts.

2. Swivel discharge chute to desired direction.

3. Affix chute by retightening knobs and nuts.

4. Additional tools are not needed.