1

4

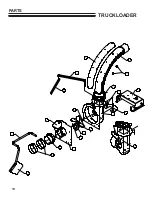

TRUCKLOADER

BEFORE STARTING THE ENGINE

1. Be familiar with the controls, how each functions,

and what each operates.

2. Check engine oil level. Add oil if necessary,

following the engine manufacturer’s

recommendations. Refer to engine manual

included with literature packet.

3. Check the air cleaner for dirty, loose, or

damaged parts. Clean or replace if necessary.

4. Check the air intake and cooling area for dirt or

debris and clean as necessary.

Gasoline is extremely flammable and highly

explosive under certain conditions. BE SURE to

install fuel cap after refueling.

Fill fuel tank with good quality, clean, unleaded

regular gasoline to the level recommended by the

engine manufacturer.

TO CHECK OR ADD FUEL:

-

Use a funnel to avoid spilling.

-

Do it outdoors.

-

Do not smoke.

-

Stop the engine; allow to cool.

-

Do not overfill.

-

Clean up spilled fuel.

STARTING THE ENGINE

1. Turn the engine and fuel lever on and move the

throttle to the half open position.

2. Move the choke to the ON position for cold

starts. For warm starts attempt to start without

the choke first to avoid flooding. If the engine

does not start then use the choke.

3. Pull the recoil starter handle firmly to start the

engine.

4. When the engine starts, gradually back off the

choke until the engine runs with no choke.

OPERATION

INTENDED USE

This unit is intended for vacuuming leaves, clippings and other similar sized organic material from the ground

into a truck or trailer. Large sized or long stringy material will tend to clog.

Vacuuming sand, rocks, and hard litter will shorten the life of this machine and may damage the machine or

parts of

it.

PRE-OPERATION CHECK LIST

(OPERATOR’S RESPONSIBILITY)

-

Review and follow all safety rules and safety

decal instructions.

-

Check that all safety decals are installed and in

good condition. Replace if damaged.

-

Check to make sure all shields and guards are

properly installed and in good condition.

-

Make sure the discharge chute and hose are

installed.

-

Check the hose, discharge chute, liners, and

housing for wear. Do not operate if these parts

are worn through. Replace or repair before

operating.

-

Check that all hardware is properly installed and

secured.

-

Check to be sure engine is free of dirt and

debris. Pay particular attention to the cooling

fins, governor parts and muffler. Clean air intake

screen. Check air cleaner; service if necessary.

-

Clean area around the oil fill dipstick. Remove

dipstick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if

necessary but

Do Not Overfill.

See engine

manual for oil specifications. Install dipstick

assembly firmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

fill tube when engine is running.

-

Inspect material to be vacuumed and remove

stones, branches or other hard objects that

might damage the machine or cause it to clog.