1

7

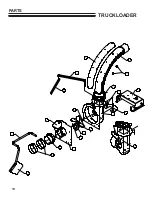

TRUCKLOADER

MAINTENANCE / STORAGE

STORAGE

To prevent possible explosion or ignition of vaporized

fuel, do not store equipment with fuel in tank or

carburetor in an enclosure or enclosed area with an

open flame (for example, a furnace or water heater

pilot light.)

Before the equipment is put into storage for any

period exceeding 30 days, the following steps

should be completed.

1. Drain all fuel from the fuel tank and the fuel lines.

Drained fuel may only be stored for 30 days. If

a stabilizer is chosen, follow the manufacturer's

recommendation by adding the correct amount of

additive for the amount of fuel to be stored. Fill

the tank with this clean, fresh gasoline and run the

engine for 2 to 3 minutes to get the stabilized fuel

into the carburetor.

2. Start the engine and run until all the fuel is used

from the carburetor float bowl and the engine

stops.

3. While the engine is still warm, drain the crankcase

oil and replace with the proper weight oil

corresponding to the season the equipment will be

used next.

4. Remove the spark plug and squirt a small amount

of engine oil into the cylinder. Reinstall the plugs

and ground spark plug leads- DO NOT connect

the leads to the plugs. Crank the engine two or

three revolutions.

5. Store the unit and all of it's components in a

clean, dry, well ventilated, non-child accessible,

sheltered area that is out of sun light and high

ambient temperatures.

To put the equipment into service after an

extended period of storage.

1. Check for loose parts and tighten if necessary.

2. Fill the fuel tank and then check the engine oil

level. Top off if necessary. See engine manual for

details.

3. Start the engine and check for fuel leaks. Repair

any leaks before operating the unit.