29

QUICKCAT

MAINTENANCE / STORAGE

CLEANING MACHINE

Clean the machine after use. Compressed air is

recommended. Do not use a pressure washer. The

machine will run cooler and last longer if kept free of

clippings and other debris. A clean machine also re-

duces the risk of fire due to accumulation of combus

-

tible debris and chaff.

Brush or blow clippings and debris off the cutterdeck

and engine deck. Clippings and debris should be

kept from accumulating around the exhaust system

and under the exhaust guards. This can be doen

by using compressed air. DO NOT use a pressure

washer.

WASHING MACHINE

CAUTION: Improperly washing a machine can cause

water to enter bearings and other components. This

can greatly reduce component life.

– Do not use a pressure washer. Do not direct

water at bearings or seals. High pressure water

can blow past seals and enter sealed bearings.

– Allow the machine to cool down before washing.

Water on a warm machine can be sucked into

sealed bearings as they cool.

– Avoid getting electrical connections wet. Water

can cause electrical faults and corrosion of elec-

trical components.

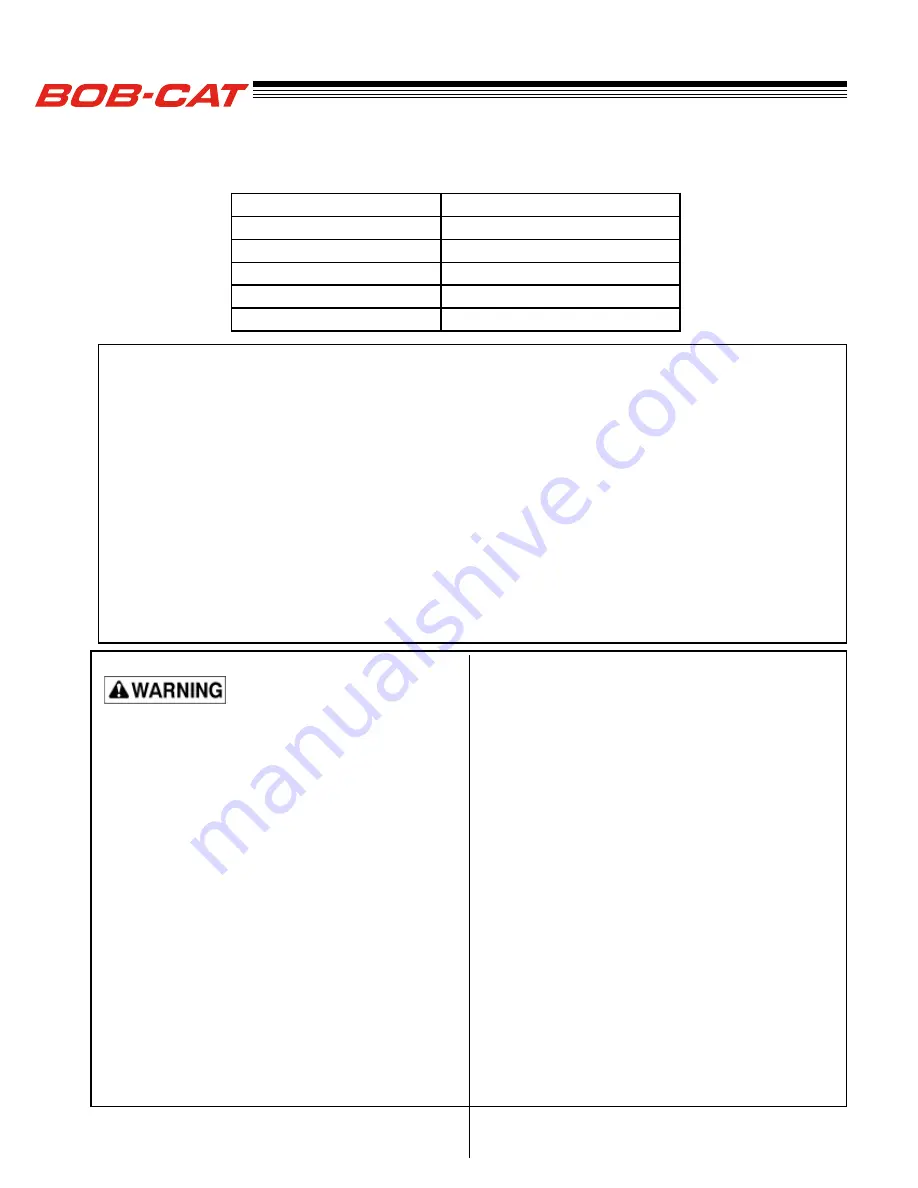

SPECIFIC TORQUES

BLADE BOLTS

70 FT-LBS (95 Nm)

WHEEL LUG NUTS

75-100 FT-LBS (102-135.5 Nm)

CLUTCH MOUNTING BOLT 50 FT-LBS (68 Nm)

TRANSAXLE PULLY BOLT

28.3-41.5 FT-LBS (38-56 Nm)

TRANSAXLE DRAIN PLUG 15-20 FT-LBS (20-27 Nm)

TRANSAXLE FILTER

100-150 IN-LBS (14.6-16.9 Nm)

STORAGE INSTRUCTIONS

To prevent possible explosion or ignition of

vaporized fuel, do not store equipment with fuel

in tank or carburetor in enclosure with open flame

(for example, a furnace or water heater pilot

light).

Daily Storage

1. Check engine oil level and air filter element daily.

2. Check oil level in gear case.

3. Close fuel valve at bottom of fuel tank.

4. Clean cutting blade (grass, dirt, etc.).

EXTENDED STORAGE

Before the equipment is put into storage for any

period exceeding 30 days:

1. Drain all fuel from fuel tank and lines (use a

hose or fuel line, routed from fuel tank shut-off to

proper container).

2. Start engine and run until all fuel is used from the

carburetor float bowl.

3. While engine is warm, drain the crankcase

oil and refill with the proper weight of oil

corresponding to the season when the equipment

will next be used.

4. Remove the spark plug and squirt a small

quantity of engine oil into the cylinder. Turn the

engine over a few times to distribute the oil.

5. Lubricate all lubrication fittings.

6. Clean and oil cutting blade to prevent rust.

To put equipment into operation after an

extended storage:

1. Fill fuel tank with clean fresh fuel.

2. Check crankcase oil level, and start engine.

3. Check fuel system for fuel leaks.