9

Hydro

Midsize

CONTROLS

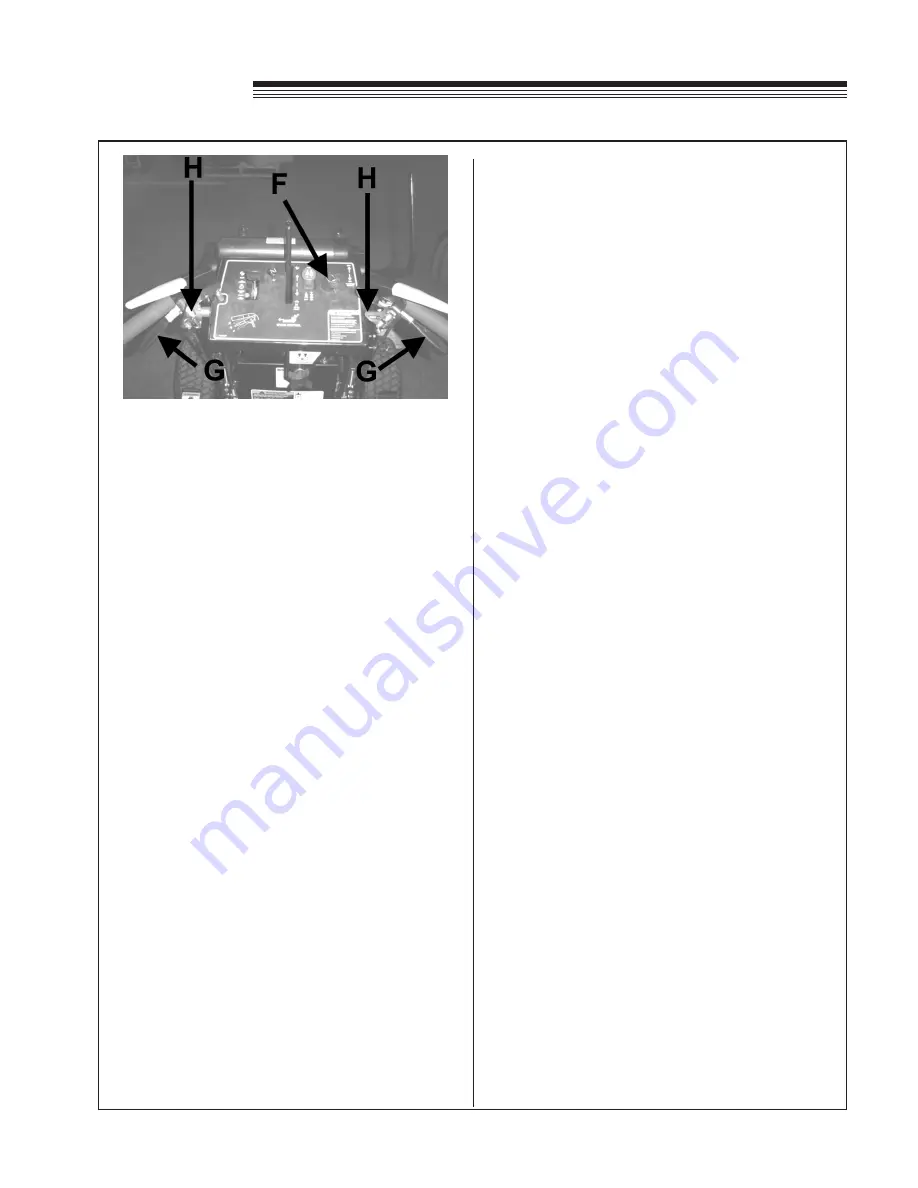

KEYSWITCH (F)

Recoil models: Turn to right to allow engine to be

started. Turn key to left to stop engine.

Electric start models: Turn key to right and hold until

machine starts. When machine starts, let go of key

and it will return to run position. Turn key to left to

stop engine.

TRACTION CONTROL LEVERS (G)

TRACTION LOCKS (H)

The traction locks provide a neutral position when

pulled back and locked with traction control levers.

To release

: pull the traction control levers up enough

to push forward on the locks.

NOTE

:

•

Squeezing the traction levers past the neutral

position will cause the machine to back up)

•

Both traction control levers must be released

at the same time in order to go straight ahead.

Using one traction control lever will cause the

machine to turn to one side.

•

When using the locks to provide a neutral position

be sure the traction control rods are fully seated in

the rear notch of the traction locks. Failure to do

this may result in serious injury.

The traction control levers have

five

functions:

1

. To provide a neutral position to stop the machine

or to start the engine. Squeeze the levers enough

to engage the traction lever locks by moving the

tops of the locks towards the handgrip, then re-

lease the levers.

2

. To engage the drive to wheels: gradually release

the traction control levers to the speed set by the

speed control and throttle.

3

. To stop: pull the levers up to neutral.

4

. To steer the unit: pulling up on the R.H. lever will

initiate a R.H. turn and pulling up on the L.H. lever

will initiate a L.H. turn.

5

. To back up: squeeze the levers equally past

neutral. This may be done any time the engine

is running and the speed selector is not set in

neutral, allowing instant forward/reverse operation

and zero turning with one wheel driving forward

and one wheel driving backward. Releasing the

traction lever from reverse automatically returns

the machine to neutral or the preset forward

speed, depending on where the traction locks are

set.

NOTE:

There is a noticeable difference in the force

required at the traction levers in the transition from

neutral to reverse.