17

Hydro

Midsize

ADJUSTMENTS

TRACTION DRIVE HYDROSTAT ADJUSTMENTS:

The following adjustments must be done in order.

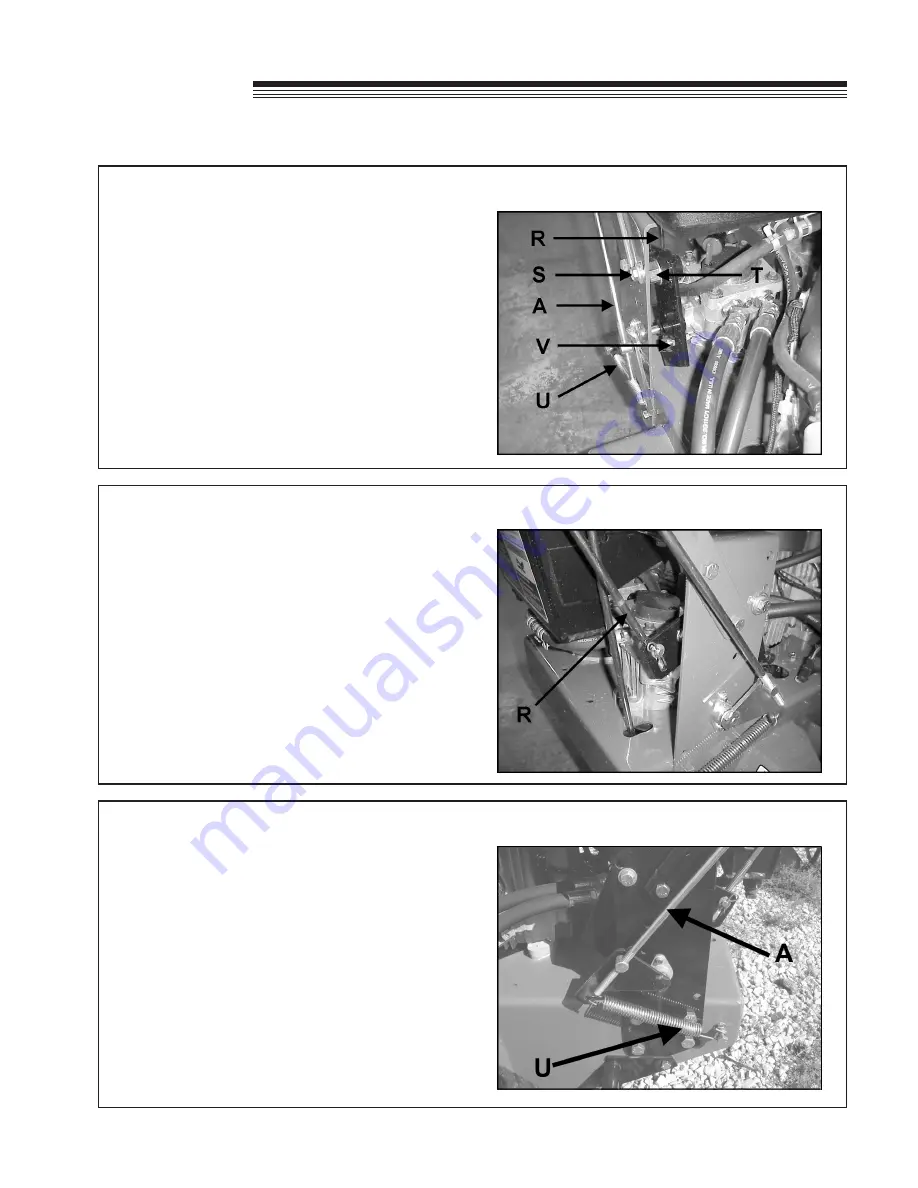

STEP 1 - Set Neutral

Neutral is set at the factory. If it should require

adjustment, raise the wheels off the ground by setting

the machine on jackstands or blocks. Disconnect

the traction control rod

A

and speed control rod

R

at each pump end. Disconnect pump arm spring

U

from bolt on engine deck. Loosen bolt

S

securing the

neutral plate eccentric shaft just enough to turn the

shaft. Start the engine and run at low speed. Turn

eccentric shaft

T

to raise or lower the point at which

the follower bearing is held in the center of the “

V

”

until the wheels stop turning. Tighten the eccentric

shaft bolt. Increase the throttle setting and check the

adjustment. Readjust if necessary. Shut the engine

off before proceeding to steps 2 and 3.

STEP 2 - Adjust Speed Control Rods

First adjust neutral, as outlined in Step 1. Set speed

control levers to neutral. Adjust swivels on lower

ends of speed control rods

R

so they just go into top

of the slots on the neutral plates.

NOTE

: If the speed control levers do not have

adequate tracking adjustment, the swivel on one of

the rods needs to be turned 1 turn.

STEP 3 - Adjust Traction Levers

Set neutral and adjust speed control rods as outlined

in Steps 1 and 2. Set traction locks in the neutral

position. Grasp traction rod

A

and pull down on it to

take out any slack. The pump control arm has some

back and forth play. Adjust the swivel to the center

of the control arm play. Connect the swivel to the

control arm. Reattach pump arm spring

U

to bolt on

engine deck.

NOTE:

More reverse speed may be gained by

adjusting the swivel to the rear of the control arm

play. A minimum of 1/16" play is required so the

traction controls can be put in neutral without the

machine backing up.