22

QUICKCAT

MOWERS

®

MAINTENANCE

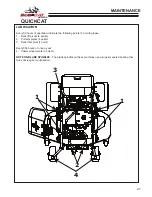

TRANSAXLES

Inattention to proper safety, operation, or

maintenance procedures could result in personal

injury, or damage to the equipment. Schiller

Grounds Care, Inc. recommends returning the

machine to your authorized Schiller Grounds

Care, Inc. dealer for service or repair.

Perform transaxle maintenance with the engine off,

spark plug wires disconnected and PTO disengaged.

TRANSAXLE FLUID CHANGE

Change the transaxle fluid every 200 hours of

operation. It is essential that the exterior of the

transaxle be free of debris, prior to fluid maintenance.

1. Remove the three 1/4" filter guard screws and

filter guard

A

. Remove the oil filter

B

from the

transaxle and discard. Dispose of used oil in ac-

cordance with local requirements.

2. Wipe the filter base surface off and apply a film

of new oil to the gasket of the new replacement

filter. Install the new filter by hand, turn 3/4 to

one full turn after the filter gasket contacts the

filter base surface.

3. Re-install the filter guard and torque the three

screws to 65 in. lbs. each.

4. Remove cap

C

, fill the transaxles through the

expansion tank

D

with approximately 2 quarts of

SAE 20W-50 engine oil PER TRANSAXLE.

Do not overfill! If you overfill the transaxle while the unit

is "cold", it may overflow as it reaches normal operating

temperatures. The oil level should not be above the

manufacturer's suggestions. The oil level should be

filled up to the full cold line on the overflow tank. This

will allow the space needed for the oil to expand as it

warms up.

5. After starting engine, check the fluid level and

continue to add oil to overflow tank

D

to fill line

on tank.

6. Purge the transaxles, following the purging pro-

cedures.