15

430

MAX

OPERATION

DRIVING

1. Select desired engine speed with the throttle. For

power driven attachments, the engine is normally

run at maximum RPM.

2. Vary vehicle speed with the Forward - Reverse

control lever. If the attachment or a steep slope

causes excessive drop in engine RPM; reduce

ground speed.

Do not lug the engine at

reduced RPM

.

3. Operate mower and other similar front mounted

attachments with front lift lever in “FLOAT”

position.

3. Safety seat switch requires operator to be seated

when PTO is “ON” or engine will stop. Disengage

PTO before attempting to start engine.

4. The hydrostatic transmission provides a braking

action when the Forward - Reverse control lever is

returned to neutral.

5. Set parking brake and stop engine before

dismounting.

6.

DO NOT TOW!

Serious damage to hydraulic

system will result. See below for emergency

moving instructions.

EMERGENCY TOWING INSTRUCTIONS

FOR A STALLED UNIT

1. Both transaxles must be in neutral before moving

a stalled unit. Neutral position is between HIGH

(2) and LOW (1) range position.

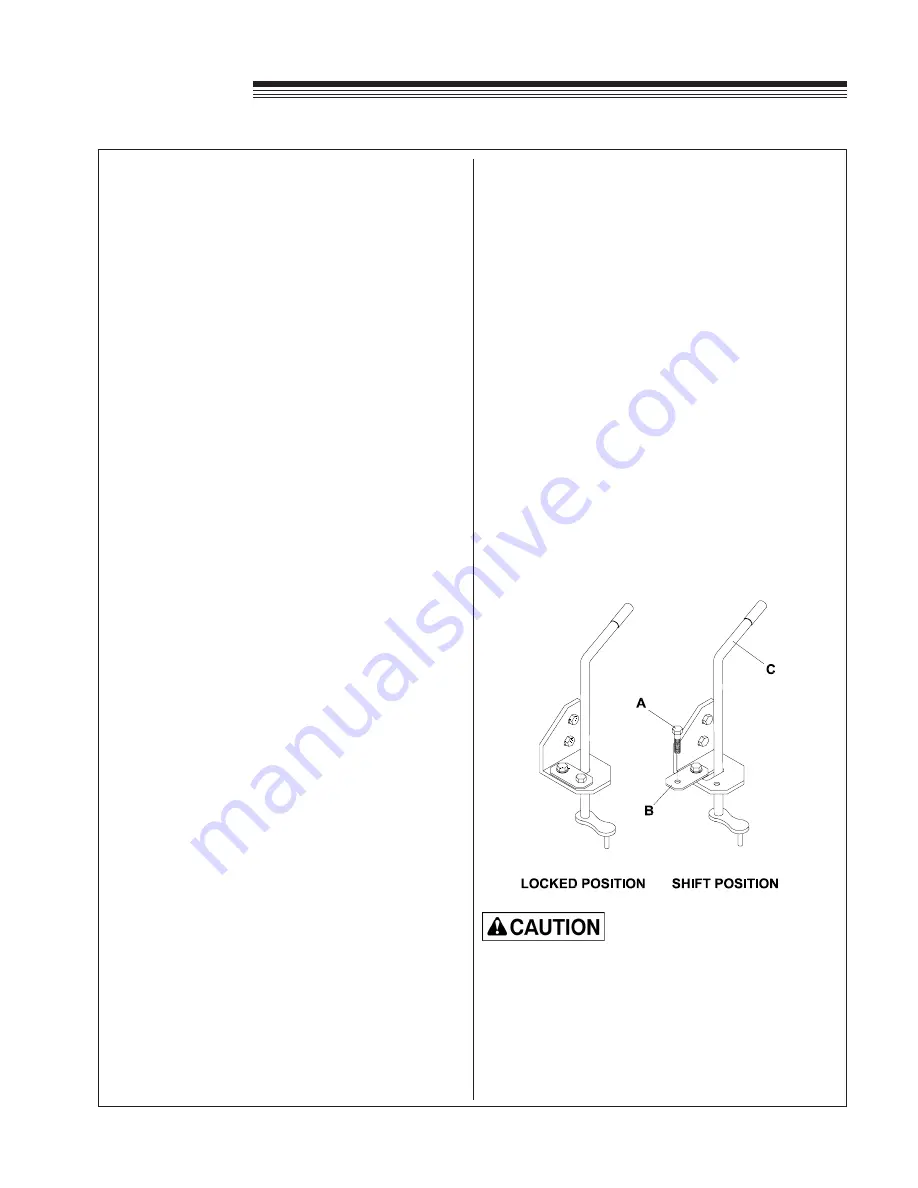

2. Release the locking straps

B

on both transaxles to

shift into "Neutral".

Failure to shift transaxles into "Neutral" will

cause serious damage to the hydrostatic

system.

3. Remember to lock the lever lock strap after

towing.

HIGH-LOW RANGE SELECTION

A locking device has been installed on the gear

range selector levers. The units are shipped with

the transaxle gear range selector in HIGH (2) range.

This range selection is recommended for most of

the operating tasks. If slower speeds and more

responsive F-R control is needed, use LOW (1)

range selection.

INSTRUCTIONS FOR TRANSAXLE

RANGE SELECTION

Do not attempt to select ranges on slopes or

when the unit is traveling. Select ranges only

on level surfaces.

1. Stop the unit on a level surface and set PARKING

BRAKE.

2. Stop the engine and dismount.

3. Remove the 1/4 x 3/4 flange bolt

A

from the lever

lock strap

B

and swing it away from the lever,

revealing a slot. (see diagram below)

4. Shift the range selector lever

C

, observing the

2 - N - 1 decal for range selection. A slight rocking

motion of the unit may be needed to fully engage

the selector.

5. With the selection completed, replace the lock

strap

B

and tighten the 1/4 x 3/4 flange bolt

A

to 12 - 15 ft. lbs. torque. (See Locked Position

drawing.)

6. Repeat step 3, 4, and 5 for the other transaxle.

Be sure to shift both transaxles into the same

range or serious mechanical damage will result!

DO NOT OPERATE UNIT WITHOUT THE LEVER

LOCK STRAPS IN THE LOCKED POSITION!