21

430

MAX

MAINTENANCE

HYDRAULIC SYSTEM

NOTE:

THE USE OF ANY OIL OTHER THAN Schiller

Grounds Care, Inc. TRANS-HYDRAULIC OIL

OR TRC 6440 UNIVERSAL TORQUE FLUID IS

NOT RECOMMENDED. IF A SUBSTITUTE OIL

CAUSES OR SUBSTANTIALLY CONTRIBUTES

TO A FAILURE, THAT FAILURE MAY NOT BE

COVERED BY WARRANTY.

1. Keep system filled with proper fluid.

- Check daily at both transaxle dipsticks.

- Check when oil is cold.

- Use only clean containers. Keep it clean!

2. Keep oil and filter changed.

- Initial filter change 25 hours, then oil and

filter change at 50 hours.

- Change oil and filter every 250 hours thereafter

or annually. (whichever occurs first)

- Change oil when warm (not hot).

- Make sure filter is primed.

- Use only O.E.M. filter and Schiller Grounds

Care, Inc. fluid or

TRC

6440.

- Check oil level after 30 minutes of operation.

- Do not over tighten drain plug.

- Make sure filter is tight.

- Change hydraulic oil and filter at the first sign

of abnormal hydraulic functions.

3. Check for leaks daily (Never operate a unit if a

leak is detected).

- Inspect hoses for leaks or chafing.

- Inspect fittings and hose ends for seepage.

4. Keep tractor/unit clean.

- Keep auxiliary hoses and couplers clean and

plugged.

- Grass and debris will hold in heat.

- A clean unit is easier to work on and safer to

operate. And it is easier to do regular checks.

- See your dealer for a high pressure filter of the

entire system if drive system has been opened

(such as hoses removed, pump or motors

removed).

TRANSAXLE OIL CHANGE PROCEDURE

Change oil and filter at any time contamination is

suspected. Approximately 3 gallons of approved

hydraulic oil are needed to change oil.

1. It is best to drain transaxles after the tractor has

been thoroughly warm to assure maximum drain.

2. Remove fill neck cap from rear transaxle.

3. Remove drain plug from rear transaxle.

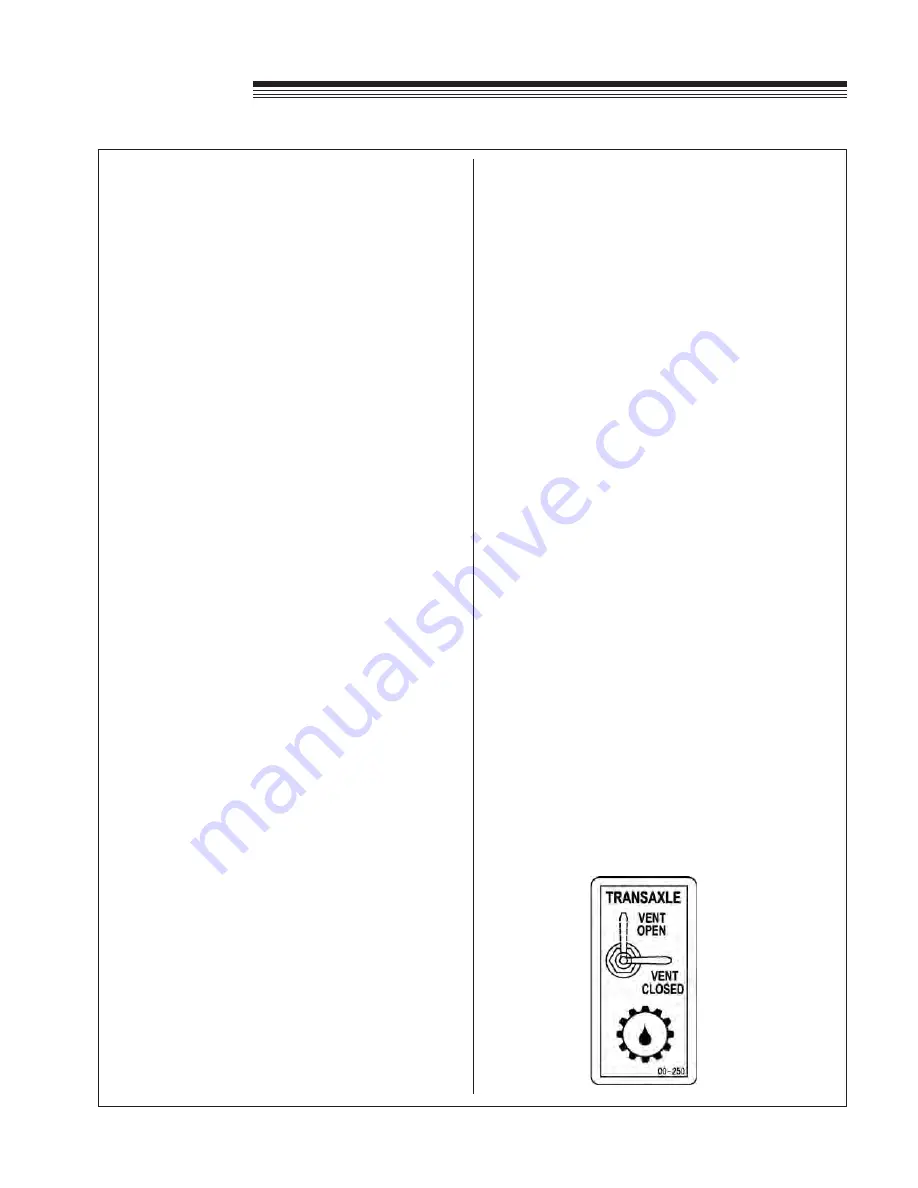

4. Open the front transaxle vent.

5. Remove drain plug from front transaxle. After

approximately 1 quart of hydraulic oil has been

drained from the front transaxle, remove the fill

tube cap.

6. Remove hydraulic oil filter and wipe filter base

clean.

7. Fill the new O.E.M. hydraulic filter with hydraulic

oil and lube the filter gasket.

8. Install the new hydraulic oil filter. Tighten 3/4 to

1 turn after gasket makes contact with the filter

base. Do not overtighten.

9. Install drain plugs in both transaxles.

10. Fill front transaxle to the top of the fill tube,

approximately 6 quarts.

11. Close the front transaxle vent.

12. Fill the rear transaxle to the top of the fill neck.

13. Run engine, and turn steering wheel extreme

right to extreme left several times to purge all air

from the circuit.

14. Drive the unit back and forth about 50 feet to

purge air from the drive circuit.

15. Repeat step 12 as needed.