Bedienungsanleitung SIGNOMAT S1

Operating instructions SIGNOMAT S1

15

Mode d´opération SIGNOMAT S1

Schilling Marking Systems GmbH

In Grubenäcker 1 DE-78532 Tuttlingen

++49 (0)7461 9472-0

++49 (0)7461 9472-20

info@marking-systems.de

www.marking-systems.de

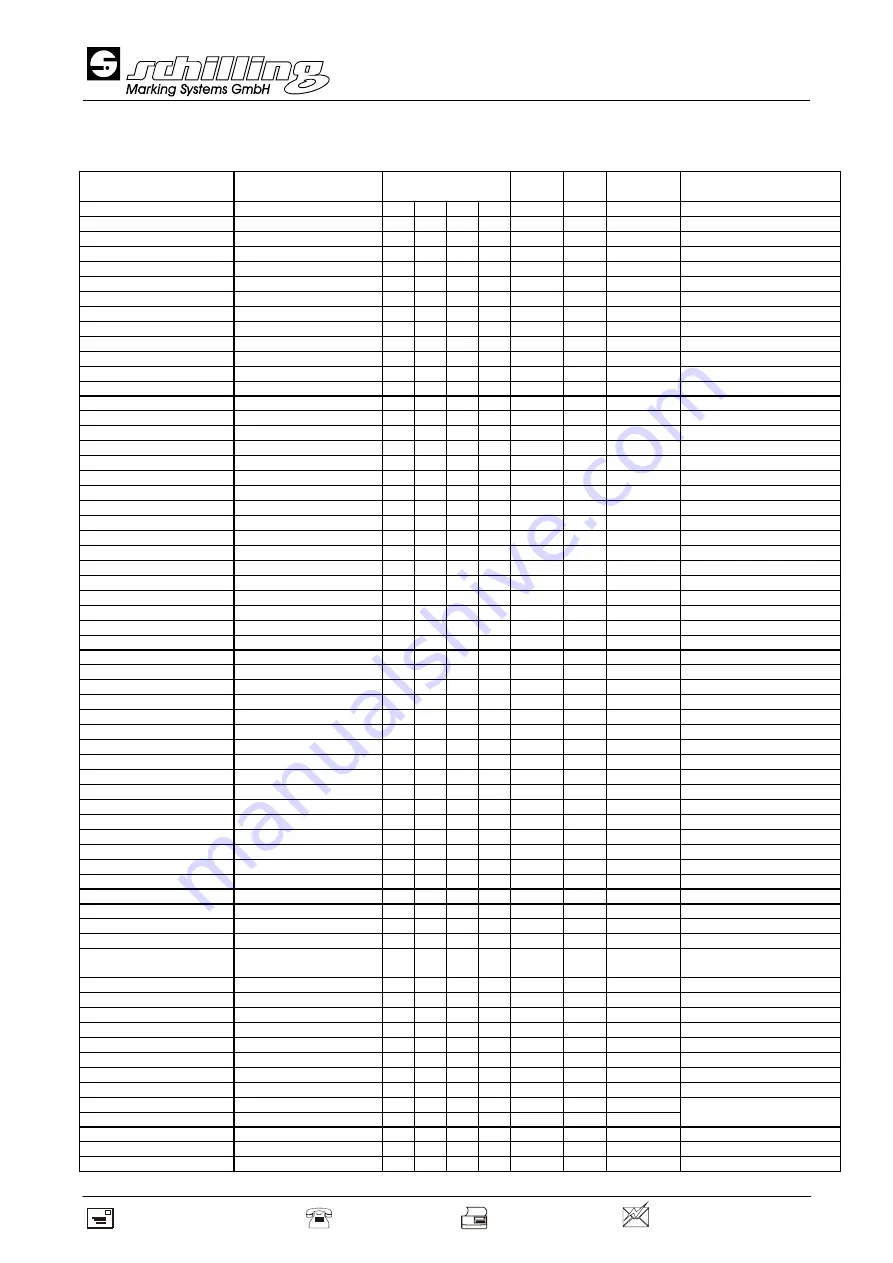

Electrolytes:

All data were determinated by experiment and are not generally applicable. A special hotline has been provided for our customers.

Material

Composition

Electrolyt AE no.

Time

Volts Type of

current

Notes

Aluminium

anodized

5,0 s 24 V

light

Mark before anodizing.

Aluminium

30,0 s 24 V

light

Marking depth approx. 0,1m

Aluminium

contains Pb

5,0 s 24 V

light

Aluminium

contains Si

12

2

5,0 s 24 V

light

Aluminium

contains Mg

12

2

5,0 s 24 V

light

Aluminium

contains Mn

12

2

5,0 s 24 V

light

Berilium

11

1

3,5 s 12 V

dark

Lead

30

5,0 s 24 V

dark

Bronze

25

3,5 s 12 V

dark

Chrome, cobalt alloy

dental alloy

10

4,0 s 12 V

dark

Chrom, hard

3

20

5

3x3,0s 12 V

dark

Chrome, bright finish

Ms + Ni + Cr

1

5

21

24

4,0 s 12 V

dark

Chrome, matte finish

Ms + Ni + Cr

1

5

21

24

4,0 s 12 V

dark

Chrome, matte finish

Fe + Cr

21

3

24

4,0 s 12 V

dark

Chrome, black

Fe + Ce

10

11

20

3,0 s 12 V

dark

Chrome, black

Ms + Cr

10

11

20

3,0 s 12 V

dark

2-4,5 s depend. on chrome type

.

Hard metal

26

30

12

4,0 s 12 V

dark

Without neutralisation

Chromed plastic

Cu + Ni + Cr

1

5

10

20

3x3,0s 12 V

dark

Short time,felt piece exchange

Copper

25

3,0 s 12 V

dark

Chromed copper

Cu + Cr

25

3x3,0s 12 V

dark

Brass

25

4,0 s 12 V

dark

Chromed brass

Ms + Ni + Cr

5

21

24

20

4,0 s 12 V

dark

Chromed brass

Ms + Cr

25

3x3,0s 12 V

dark

Brass, gold plated

Ms + Ni + Au

10

20

2x5,0s 12V

dark

Alpaca

25

3,0 s 12 V

dark

Nickel, electroplated

11

1

4,0 s 12 V

dark

Nickel, chemical

3

4,0 s 12 V

dark

Heavy metal

12

7,0 s 12 V

dark

Without neutralisation

Steel 1.0503

10

20

29

4,0 s 12 V

dark

Aftertreatment:N2+ K1

Steel 1.1274

10

20

24

3,0 s 12 V

dark

Steel 1.4021

1

8

10

20

4,0 s 12 V

dark

Steel 1.4024

10

20

4,0 s 12 V

dark

Steel 1.4034

8

10

20

2,0 s 24 V

dark

Steel 1.4036

8

11

20

4,0 s 12 V

dark

Steel 1.4057

11

12

10

4,0 s 12 V

dark

Steel 1.4106

8

11

4,0 s 12 V

dark

Steel 1.4110

11

12

20

4,0 s 12 V

dark

Steel 1.4117

1

24

20

10

4,0 s 12 V

dark

Steel 1.4125

20

10

7

3

4,0 s 12 V

dark

Steel 1.4212

11

12

10

4,0 s 12 V

dark

Steel 1.4401

11

12

3,0 s 12 V

dark

Steel 1.4435

11

1

24

4,0 s 12 V

dark

Steel 1.4571

11

12

10

21

4,0 s 12 V

dark

Steel, gunmetal finish

10

20

3

3x4,0s 12 V

dark

Steel, cadmium-plated

27

3x4,0s 12 V

dark

Steel, chrome-vanad.alloy

11

12

20

4,0 s 12 V

dark

Steel, steam annealed

3

10

4,0 s 12 V

dark

1xlight, 1xdark

Steel, high C content

29

10

20

3,0 s 12 V

dark

Aftertreatment: N2 + K1

Steel, low-alloy

29

10

20

3,0 s 12 V

dark

Aftertreatment: N2 + K1

Steel, phosphatized

3

10

3x4,0s 12 V

light

Steel, stainl., high-all

oy, hardened,glass-

blasted

20

10

12

8

4,0 s 12 V

dark

Steel, stainless

up to 1.4305

1

11

24

4,0 s 12 V

dark

Steel, stainl.,Cr-Co alloy

11

12

20

4,0 s 12 V

dark

Steel, stanl.,heat treatable

e.g. 1.4021/1.4034

8

10

11

20

4,0 s 12 V

dark

Steel, stainl.,high-alloy

implantation

12

11

10

3,0 s 12 V

dark

Steel, stainl.,high-alloy

starting at 1.4305

10

11

12

20

3,0 s 24 V

dark

Steel, stainl., blackened

10

20

2x3,0s 24 V

dark

Steel, gold-plated

Fe + Ni + Au

10

20

5

8

4,0 s 12 V

dark

2-3x3,0 s if necessary

Steel, galvanized

Fe + Zn

10

4,0 s 12 V

dark

Titanium

12

10

29

28

1,0 s 12 V

dark

Use min. electrolyte and short

Titanium

brass + titanium

25

4,0 s 12 V

dark

marking time (1x1,5s)

Vitalium

20

10

4,0 s 12 V

dark

Zinc

10

25

20

4,0 s 12 V

light

Tin

10

25

20

4,0 s 12 V

light