Installation Instructions

C

L

LEVER/

STRIKE

3 Di

3 Gi

4 Ji

4 Qi

1 Qi

15/16

DRILL FOR

#12-24

MACHINE

OR OR #12

WOOD

SCREWS

(2 PLACES)

5/32” DEEP

1 Qi

” DEEP

C

L

MPC COBRA

MPC COBRA

MANUALLY PROGRAMMABLE CYLINDRICAL

LOCKING SYSTEM

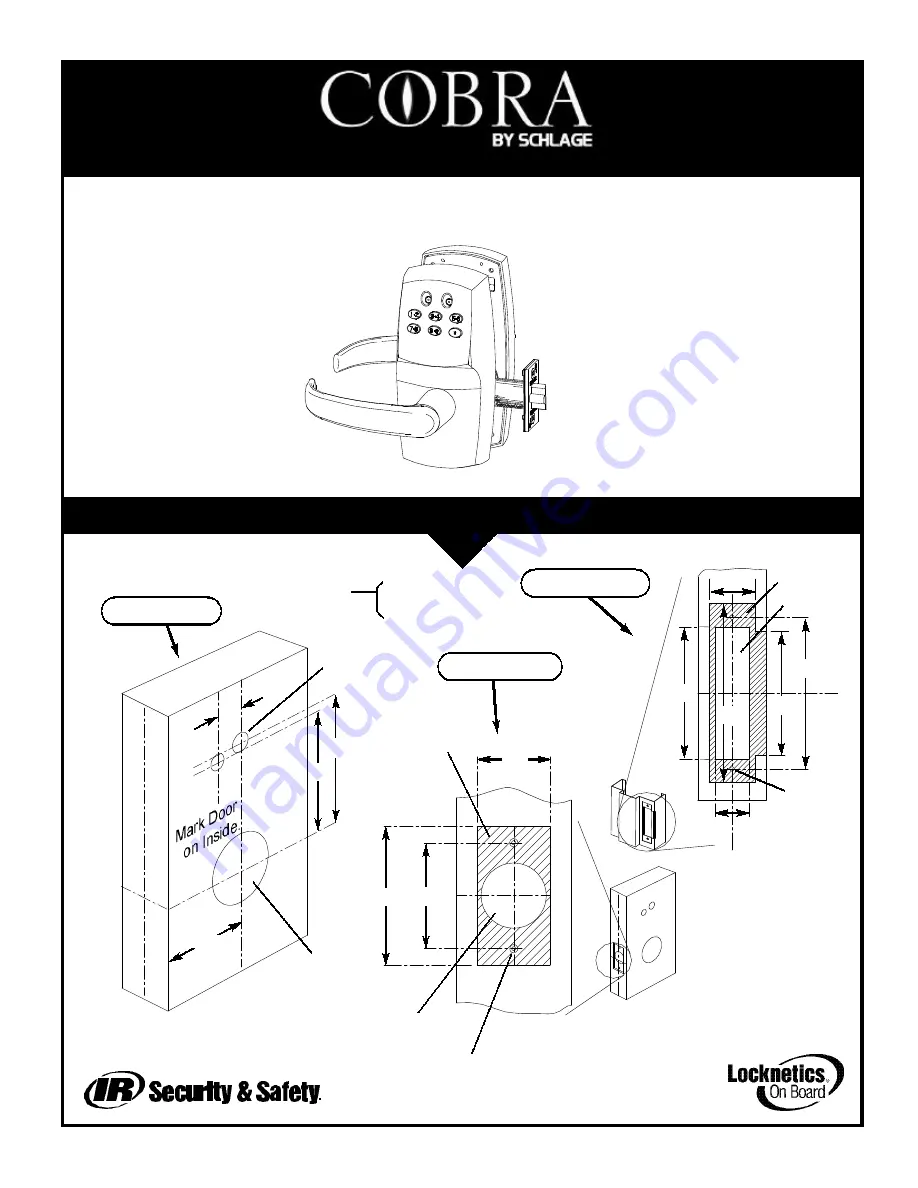

DOOR, LATCH AND FRAME PREPARATION:

11

3 Gi

3 Ji

Ji

BACKSET*

C

L

DOOR EDGE

C

L

LOCK

C

L

LEVER/

STRIKE

DOOR MUST

CORRESPOND

WITH CENTER-

LINE OF

STRIKE

2 Qr

1 iQ

1 Gi

1” HOLE INTO

2

Qi

“ HOLE

2

Qi

“ THRU

19/32”THRU

(2 PLACES)

DRILL FOR #6-32 MACHINE

OR

#6 WOOD SCREWS

(2 PLACES)

DOOR PREP

FRAME PREP

LATCH PREP

*BACKSET

=

2 Di

for OLB

(MEASURED FROM

=

2 Dr

for SLB & ELB

CENTER OF BEVEL)

Use template or information below to prep

door, latch and frame.

PROGRAMMING STEPS:

INSTALLING 7-PIN SMALL-FORMAT IC CORE FOR MANUAL KEY OVERRIDE:

3/16” DEEP

7

TO CHANGE

PROGRAMMING CODE

ENTER PROG. CODE

ENTER NEW

PROG.CODE

ENTER NEW

PROG.CODE AGAIN

*

*

*

*

33

TO ADD

TOGGLE CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

191

*

*

*

*

33

TO ADD

FREEZE/LOCKOUT CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

115

*

*

*

*

33

TO ADD

ONE TIME USE CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

113

*

*

*

*

99

TO CHANGE RELOCK

TIME DELAY

(DEFAULT 5 SEC.)

ENTER PROG. CODE

TO END

*

*

*

*

33

TO ADD

SUPERVISED CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

117

*

*

*

*

33

TO ADD

PASS THRU CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

119

*

*

*

*

TO ADD

NORMAL USE CODE

ENTER PROG. CODE

ENTER NEW CODE

TO ADD MORE

TO END

*

*

*

*

*

3

1

1

5

TO DELETE

CODES

ENTER PROG. CODE

ENTER CODE

TO DELETE MORE

TO END

*

*

*

*

*

5

PRESS 1 FOR 1

SEC. AND/OR 5

FOR 5 SEC. THE

TIMES WILL ADD.

Use the steps on this page to

program codes into the lock.

The “*” key is used like the

<ENTER> key is on a com-

puter. After pressing the “*”

key, wait for the red and

green LEDs to stop flashing

before proceeding to the next

step. If at any time the red

LED stays on while the green

LED flashes an error has

occurred. The flashing mes-

sage will repeat three times.

Count the number of flashes

and consult the error code

chart below.

FLASHES ERROR CODE DESCRIPTION

2

Code too long 8 digits max.

3

Memory full, must delete some `

codes

4

Can not delete Programming code -

use Change steps.

5

Second entry did not match first

(Programming Code)

6

Invalid entry, start over. (Verify that

any codes entered prior to this error

do not operate the lock.)

7

Code to be deleted does not exist.

8

Duplicate code, code already exists.

A. HOLD LOCK IN HORIZONTAL

POSITION AS SHOWN AND PUSH

PLUG IN UNTIL PIN FALLS OUT.

REMOVE PLUG.

B. INSERT CYLINDER CON-

TROL KEY INTO CORE AND

TURN CLOCKWISE TO

RETRACT LOCKING PIN.

C. PUSH CYLINDER CORE

INTO LOCK - RESISTANCE

WILL BE NOTICEABLE.

TURN KEY COUNTER-

CLOCKWISE TO ENGAGE

LOCKING PIN.

D. REMOVE KEY.

LOCK IS NOW

OPERATIONAL.

OPERATION:

EITHER THE CYLINDER PLUG

OR THE IC CORE MUST BE

INSTALLED FOR THE LOCK

TO OPERATE. REMOVAL OF

THE CORE OR PLUG AUTO-

MATICALLY UNLOCKS THE

LOCK. IT IS RECOMMENDED

THAT AN IC CORE BE

INSTALLED IN CASE IT EVER

BECOMES NECESSARY TO

UNLOCK THE LOCK USING

MECHANICAL MEANS.

Form 57010 Rev. A

02-22-2002

The MPC Cobra is a battery-pow-

ered manually programmed access

control system. Up to 100 individual

codes can be programmed right at

the keypad. A red and green LED

on the keypad provide visual indica-

tion for programming and access

events. Mechanical key override is

possible when a

7-pin small-format

interchangeable core

(not included)

is installed in place of the cylinder

plug, which comes standard. Either

the plug or the IC core must be

installed for the lock to operate. When the

cylinder is removed (using the cylinder

con-

trol

key) the lock will unlock. Manual key

override should only be necessary if the low

battery output indications have been ignored.

(See Battery Information on page 3). The

design allows for mounting on doors from 1-

1/2” to 2” thick. The retractor design allows

easy adjustment for door thickness by rota-

tion. A shim is available to mount the lock to

a 1-3/8” door. An exterior gasket (EG option)

is available for application to exterior sides of

doors.

Page 1 of 2

Page 4 of 4

REMOVE TAPE

(IF PRESENT)