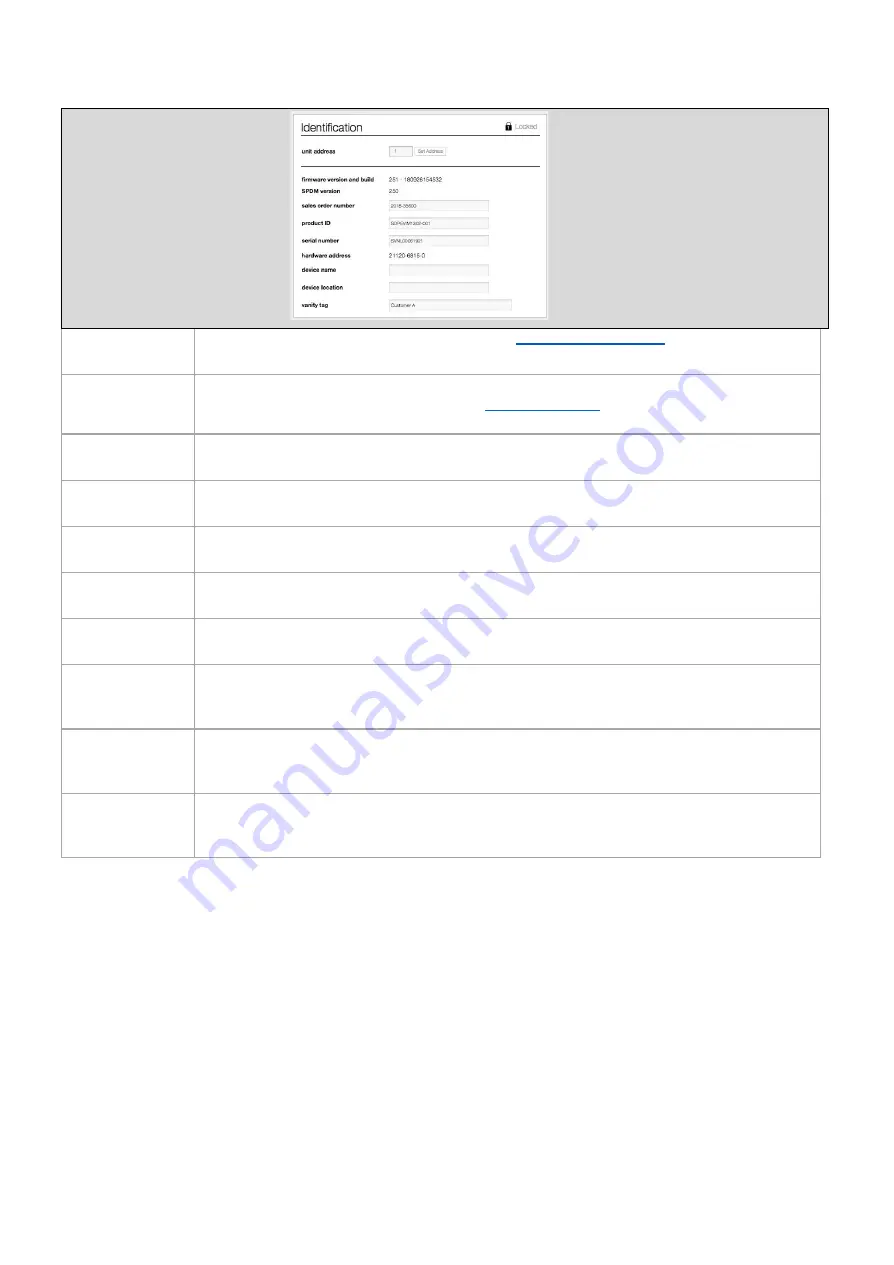

Identification

Identification and allocation information

of the device

unit address

Address of the device on the databus (see chapter

). Number can be

between 1 and 65535 (When using Modbus, number can be between 1 and 247).

firmware version

Current firmware version installed on the PDU.

➢

Please check the website for the latest version:

SPDM version

The actual version of the Schleifenbauer Products Data Model.

sales order

number

Reference of initial Schleifenbauer sales order number.

product ID

Product identification tag of the device.

serial number

Unique, sequential production number.

hardware address Unique identification of the device controller.

device name

Configurable device name, which has a maximum of 16 characters.

Note: this field is not connected with the “extended name support” and is always max 16 characters

device location

Configurable location name, which has a maximum of 16 characters.

Note: this field is not connected with the “extended name support” and is always max 16 characters

vanity tag

Configurable vanity tag, which has a maximum of 20 characters.

Note: this field is not connected with the “extended name support” and is always max 20 characters

Page 32 of 58

V262_User manual

Schleifenbauer PDU