General Description of Functions

EN-US · 30.30.01.02084 · 02 · 12/20

23 / 72

7 General Description of Functions

7.1 Picking up the Workpiece (Vacuum Generation)

The ejector is designed for handling and holding workpieces by means of a vacuum in combination with

suction systems. The vacuum is generated in a nozzle according to the Venturi principle, using suction

generated by the flow of accelerated compressed air. Compressed air is channeled into the ejector and

flows through the nozzle. A vacuum is generated immediately downstream of the motive nozzle; this

causes the air to be sucked through the vacuum connection. The air and compressed air that have been

removed by the suction exit together via the silencer.

The venturi nozzle on the ejector is activated and deactivated using the suction command:

•

In the NO (normally open) variant, the venturi nozzle is deactivated when the suction signal is re-

ceived.

•

In the NC (normally closed) variant, the venturi nozzle is activated when the suction signal is re-

ceived.

An integrated sensor records the vacuum generated by the venturi nozzle. The exact vacuum level is

shown on the display and can be read from the IO-Link process data.

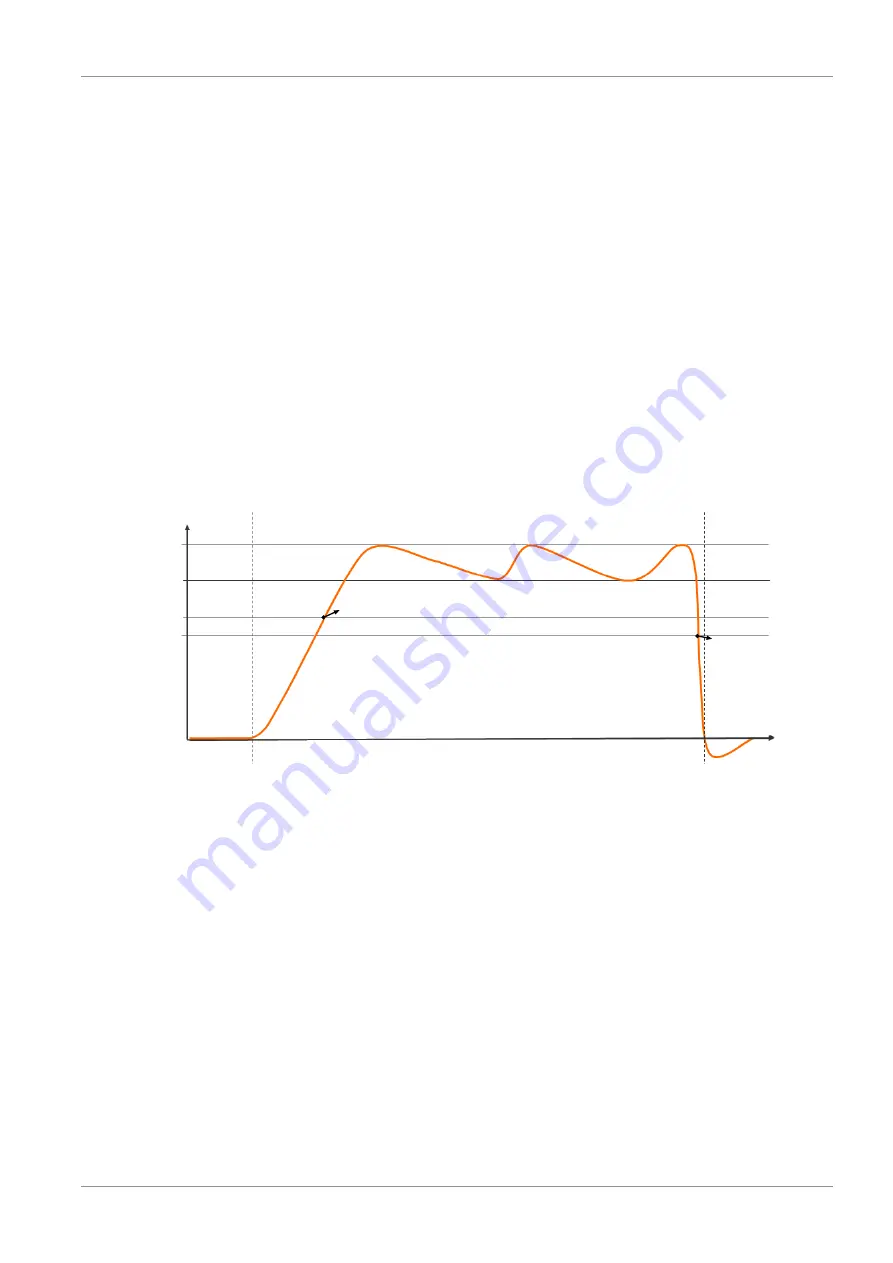

H1

H1-h1

H2

H2-h2

Vacuum

[mbar]

Vacuum on

Time [s]

OUT=on

OUT=off

The ejector has an integrated air saving function and automatically regulates the vacuum in suction

mode:

•

The electronics switch the venturi nozzle off as soon as the set vacuum limit value (switching point

H1) is reached.

•

When objects with airtight surfaces are picked up, the integrated non-return valve prevents the vac-

uum from dropping.

•

If the system vacuum drops below the limit value switching point H1-h1 due to leaks, the venturi

nozzle is switched back on.

•

Depending on the vacuum, the H2 process data bit is set once a workpiece is picked up safely. This

enables the further handling process.

7.2 Depositing the Workpiece (Blowing Off)

In blow off mode, the vacuum circuit of the ejector is supplied with compressed air. This ensures that the

vacuum drops quickly, allowing the workpiece to be deposited quickly.

The ejector provides three blow off modes for selection:

•

Externally controlled blow off

•

Internally time-controlled blow off