30.30.01.01648/06

www.schmalz.com

EN | 35

Control of FMHD

The sequence of a lifting process differs based on the integrated function and valve type used. You

can find the relevant information about this subject in the sections below.

Optimized control

Only turn on the suction when workpieces are being lifted. Otherwise, additional dust

from the environment is drawn in, which could shorten the necessary maintenance

intervals.

6.2.1

Sequential Diagram for FMHD with Separating Cylinder and “Blow off” Function

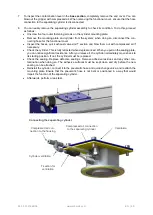

Vacuum area gripper

s FMHD are equipped with a separating cylinder and the “Blow off” function as

standard. Oversized grippers of over 2,500 mm have two separating cylinders, but the lifting process

sequence is identical.

Simplified diagram of a gripper cross-section

Vacuum reservoir

Compact cylinder (extended; vacuum reservoir and valve chamber

separated)

Valve chamber

Sealing foam

Workpiece

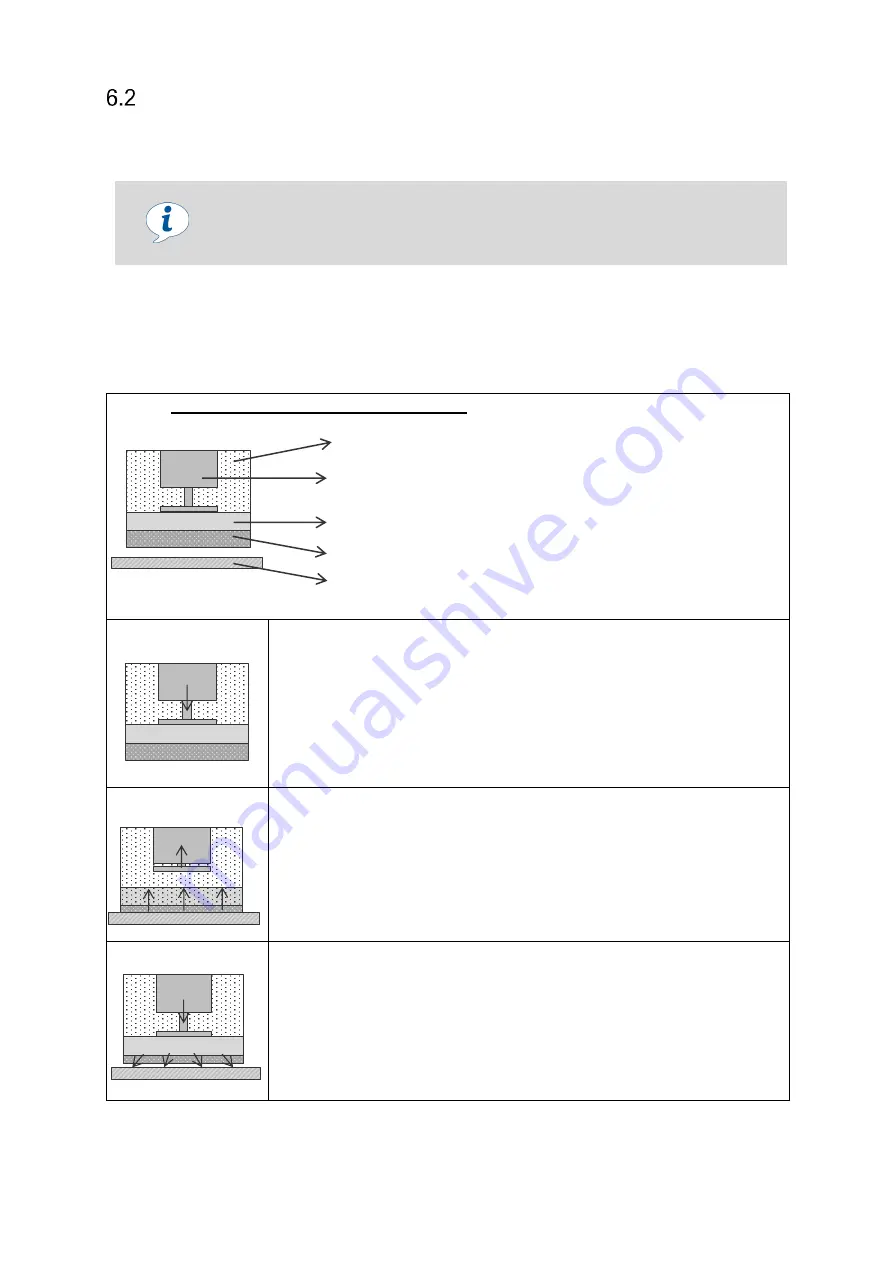

Pretensioning

Before the suction process starts, the

vacuum reservoir integrated into the suction bar must be evacuated. The

amount of time this process takes varies based on the suction bar type, vac-

uum generator capacity and the length. Generally, this process is started ap-

proximately 0.5 to 5 seconds before picking up the load.

When the “Separating cylinder” control valve is activated, the cylinder piston

rod extends and separates the vacuum reservoir from the valve chamber.

Vacuum is generated in the reservoir chamber when the vacuum generator

is switched on.

Applying suction

Once the sealing mat has been placed on the workpiece and is compressed,

the system can start picking it up.

To do so, the “Separating cylinder” control valve is reset (LED is not illumi-

nated). The cylinder’s piston rod is retracted and the load is picked up. The

load can then be transported once the necessary vacuum level is reached.

Depositing

Once the workpiece has been transported and set down, it must be depos-

ited.

For this purpose, the separating cylinder control valve is activated (upper

LED lights up). The cylinder’s piston rod extends and separates the valve

chamber from the reservoir chamber.

The “Blow off” control valve is also activated (lower LED lights up). This

causes the vacuum in the valve chamber to break down and the workpiece

to be released from the sealing mat.