Troubleshooting

76 / 96

EN

· 30.30.01.02851 · 01 · 03/22

11.3

Error Codes, Causes and Solutions

The condition monitoring functions output events that can be used to draw conclusions with regard to the process. If

a known error occurs, it is transmitted via the IO-Link ISDU parameter [0x0082] in the form of an error number.

The system status is automatically refreshed on the NFC tag every 5 minutes at the latest. That means that an error

may be displayed via NFC even though it has already disappeared.

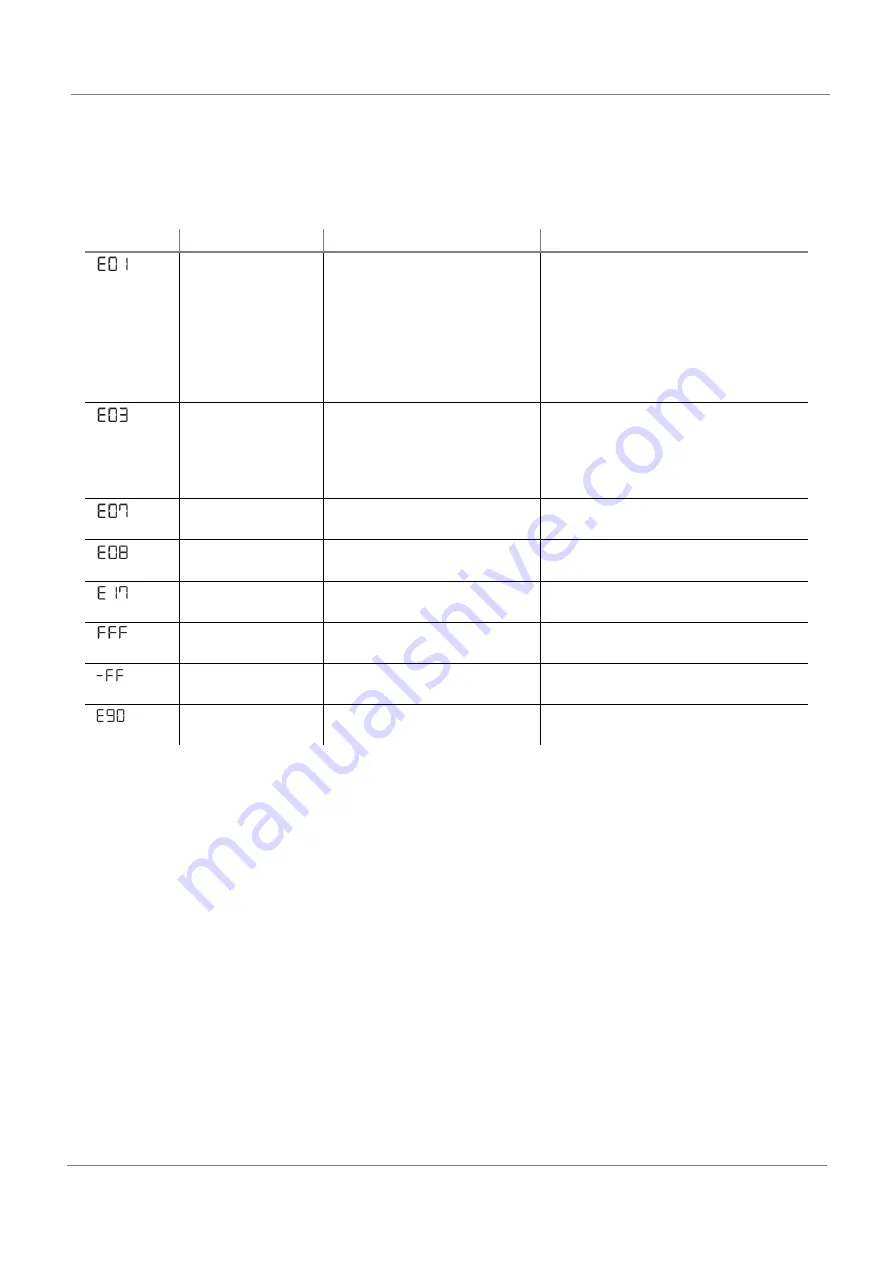

Error code

Fault

Possible cause

Solution

Internal error

Electronics

Operating voltage was

disconnected too quickly after a

parameter change, saving

process was not complete.

Clear the error by restoring the factory

setting with the [rE5] function or

parameter.

Use engineering tool to import a valid

dataset.

If error [E01] occurs again after

restarting the supply voltages:

Replacement by Schmalz required

Zero-point

error/calibration

error on vacuum

sensor

Zero-point adjustment for

vacuum sensor is outside of the

tolerance 3% FS. Calibration was

canceled when measurement

value was too high or too low.

Ventilate the vacuum circuit.

Perform calibration.

Under voltage US

Sensor supply voltage is too low. Check power supply unit and power load

Increase supply voltage

IO-Link error

Connection to master

interrupted.

Check connection line.

Repeat the power up process.

Over voltage US

Sensor supply voltage is too

high.

Check power supply unit.

Reduce supply voltage

Vacuum range

Measured vacuum level too

high, sensor defective

Check and adjust supply pressure.

Replacement by Schmalz required

Overpressure in

vacuum system

Area gripper in “blow-off” mode

No error!

Overpressure display

Manual mode

Manual mode locked by IO-Link.

If necessary, use IO-Link to enable

manual mode.