Installation

EN

· 30.30.01.02851 · 01 · 03/22

63 / 96

Processing temperature: A range of +10° C to +40° C is recommended for the object temperature

and the ambient temperature.

Note: After you have glued on the foam, it should not be used for at least one hour so that the

adhesive has time to set completely.

The sealing plate is asymmetrical. Make sure that it is correctly aligned.

We also offer oil-resistant and temperature-resistant foams (temperature > 60° C) for special applications.

9.4

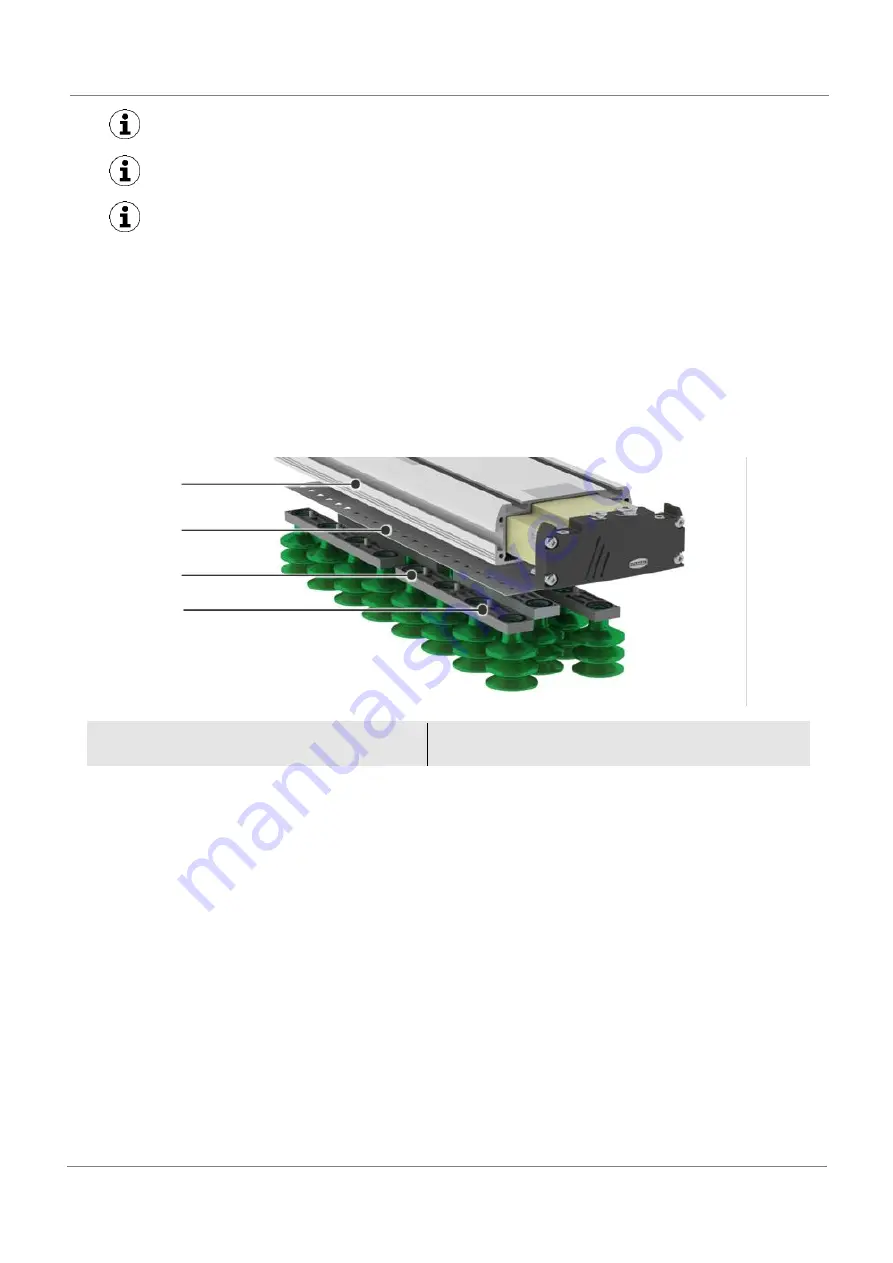

Mounting the Suction Cup Connection Strips

The suction cup connection strips are usually each equipped with four suction cups with a diameter of 40 mm or six

suction cups with a diameter of 20 mm.

When removing the strips, we recommend marking the positions in which shorter strips were mounted. This will

ensure that the suction cup connection strips are screwed back on in the correct order.

The torque is 2 Nm.

1

Main body

2

Valve film

3

Suction cup connection strips

4

M4 screws for suction cup connection strip

9.5

Mounting the Valve Film / Masking Film

When replacing the valve film (also referred to as masking film) on area grippers with suction cups, all suction cup

connection strips must first be unscrewed.

The valve film can be reused if the adhesive layer is still good enough and is not soiled. The valve film can be reused

around 4–6 times. It is therefore important to protect the adhesive side of the valve film from dust after it has been

removed.

The same sealing plate grid can be used to glue the valve film SW and the valve film SVK to the main body. When

switching from valve type SW to valve type SVK, you must first insert the ball valves specified by the manufacturer into

the opening in the main body. Small recesses in the cover make it easy to pull off the valve film.

2

3

1

4