OPERATION

30.30.01.00176/01

www.schmalz.com

EN | 37

WARNING

Falling objects when the vacuum generation fails

Risk of injuries

►

If the vacuum generation fails:

1. Sound the alarm.

2. Set the operator handle

all the way to “Lift.”

The residual vacuum allows the tube lifter and load to be lowered slowly.

3. Stay clear of the danger zone at all times.

4. If possible, set down the load safely.

6.4 Replacing the suction cups

DANGER

Ignition sources when changing the suction cup

Risk of explosion

►

►

Ensure that a potentially explosive atmosphere is not produced while changing

the suction cup.

After changing the suction cup, ensure that the suction cup has a conductive

connection to the operator handle.

Wear on suction sealing lips and sealing foams

1.

The service life of suction sealing lips and sealing foams can be extended by

putting the sealing on cleanly and avoiding lateral loads.

2.

Check the resistance of foams and sealing lips to prevailing environmental

conditions, such as ozone, acid, oil, grease, solvents etc.

3.

Sealing lips can become aged and brittle due to a number of different

environmental conditions.

4.

Visually inspect suction sealing lips in regular intervals (see chapter 9.2) and

replace them when necessary.

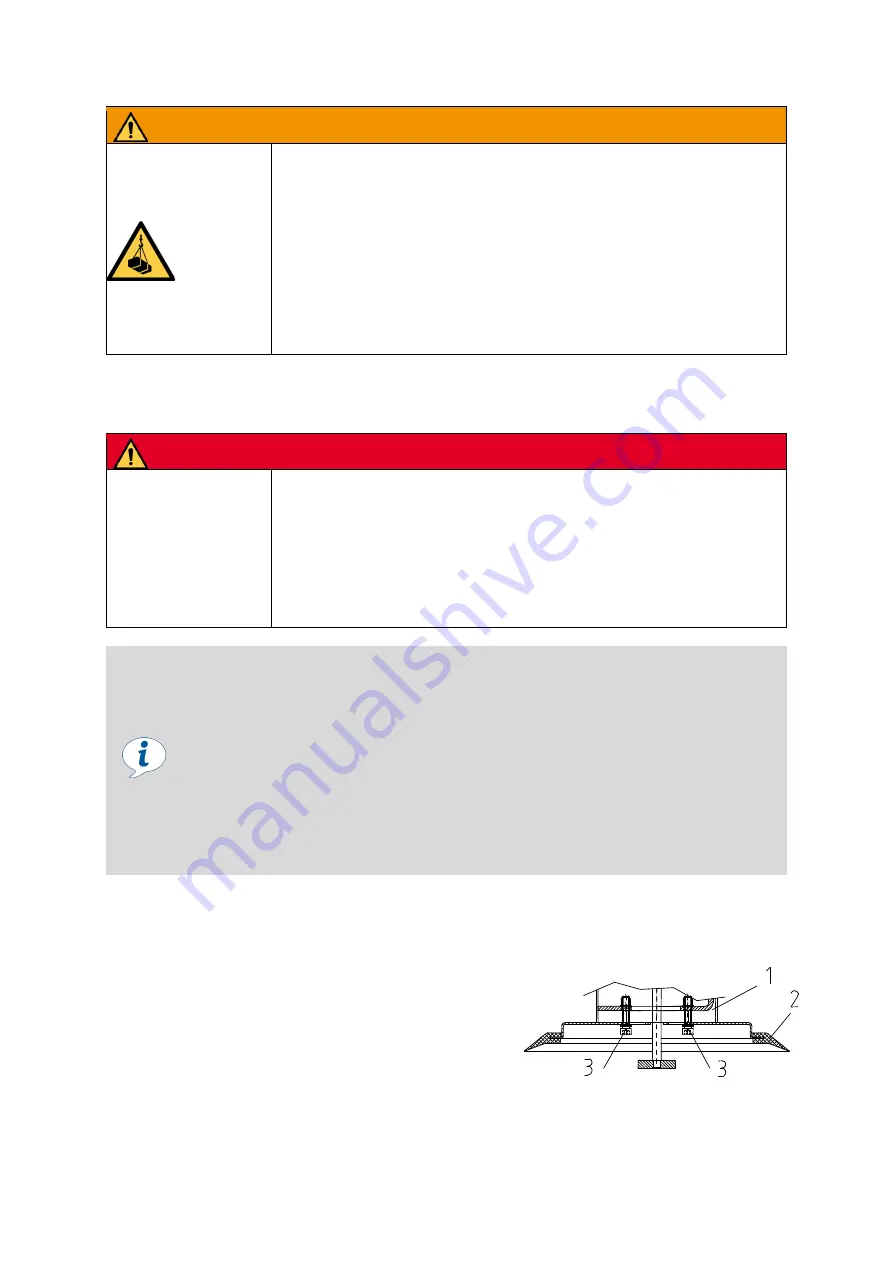

6.4.1 Without quick-change adapter

1. Switch off the vacuum generator.

2. Remove the four screws (3) from the suction cup and detach

the operator handle (1) from the suction cup (2).

3. Mount the operator handle (1) onto the other suction cup

(2).

4. Use four screws (3) (tightening torque 12 Nm for

M6/15 Nm for M8) and toothed lock washers to secure

the suction cups (2) to the operator

handle (1).

5. Inspect equipotential bonding (see chapter 5.3).