MAINTENANCE

30.30.01.00176/01

www.schmalz.com

EN | 47

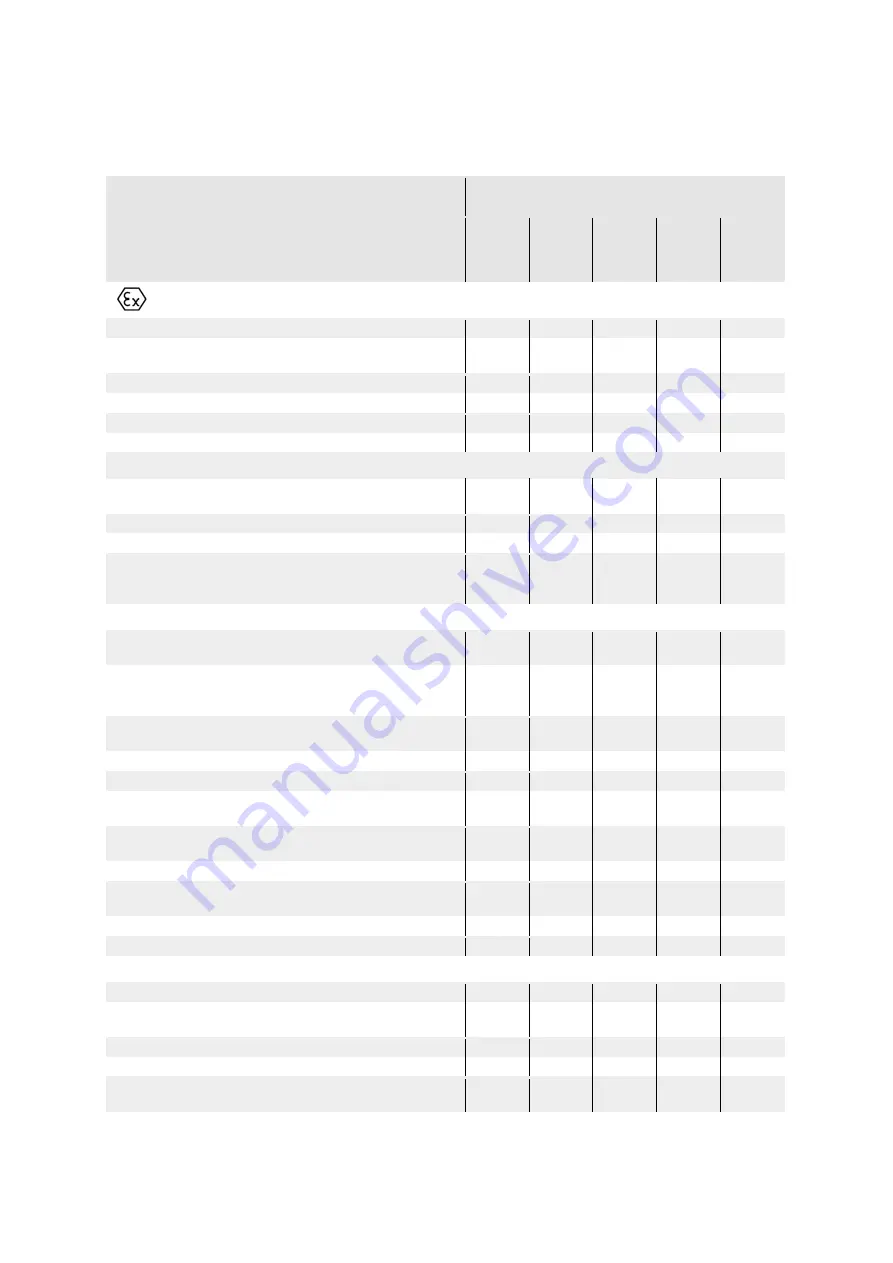

9.2 Service table

Interval

Daily

Weekly Monthly

Every 6

months

Annual

inspecti

on

(UVV)

Explosion protection

Do all the parts have equipotential bonding?

X

X

Are all grounding wires securely connected?

X

X

Are grounding wires worn or damaged?

X

X

Are all grounding connection markers in place?

X

Is there any visible corrosion or damage to parts?

X

X

Resistance measurement < 10

Ω (see chapter 5.3.2).

X

Ejector

Is the dust filter clean (see chapter 9.3)? After the fifth

clean or after two years at the latest, replace it.

X

X

Are the dust filter housing and connections sealed?

X

X

Is the vaccuum limiting valve set correctly?

X

X

Is the supply hose in good condition (not brittle, not

kinked, no worn sections, i.e. not leaking)?

Does the hose need to be untwisted?

X

X

Tube lifter

Is the dust filter in the operator handle still installed and

has it been cleaned? (See chapter 9.3.2.)

X

X

Is the lift tube in good condition

(not porous, no worn sections, no holes, and therefore

sealed)?

X

X

Is the lift tube attached properly?

(Screw clip in the correct position, correctly sealed)

X

Can the rotary union be moved easily?

X

X

Is the operator handle responsive?

X

X

Are the operating instructions still available and are

operators familiar with them?

X

X

Check all load-bearing parts (e.g. the suspension system)

for deformation, wear, rust or other damage.

X

X

Are all connections (hose clamps, etc.) secure?

X

Are the type plate, load plate and grounding connection

markers still attached and legible?

X

Is the handle or operator handle on tight?

X

Is the non-return valve sealed? (See chapter 9.1.)

X

X

X

Suction cup

Is the tube holder/suction cup seal OK?

X

X

Is the gripper seal OK? Is it free from cracks?

Is the sealing lip even, etc.? Replace if necessary.

X

X

Is the filter fleece in the suction cup cleaned?

X

X

Are the plunger guides OK?

X

Are the hose connections OK and are the hoses sealed?

(For double and four head suction grippers)

X

X

Function