INSTALLATION

30.30.01.00176/01

www.schmalz.com

EN | 25

5

Installation

Installation must be performed only by qualified electrical and mechanical specialists (see chapter

1.8).

DANGER

Sources of ignition during installation

Risk of explosion

►

Ensure that a potentially explosive atmosphere is not produced during

installation.

An explosion protection representative commissioned by the operator must check and approve the

entire plant (the items included in the delivery from J. Schmalz GmbH and the customer-side

installation) in accordance with ATEX 1999/92 EC and the national regulations before the start of

operations.

5.1 Installing compressed air supply

1. Ensure no dirt particles are able to enter compressed air

supply system during installation.

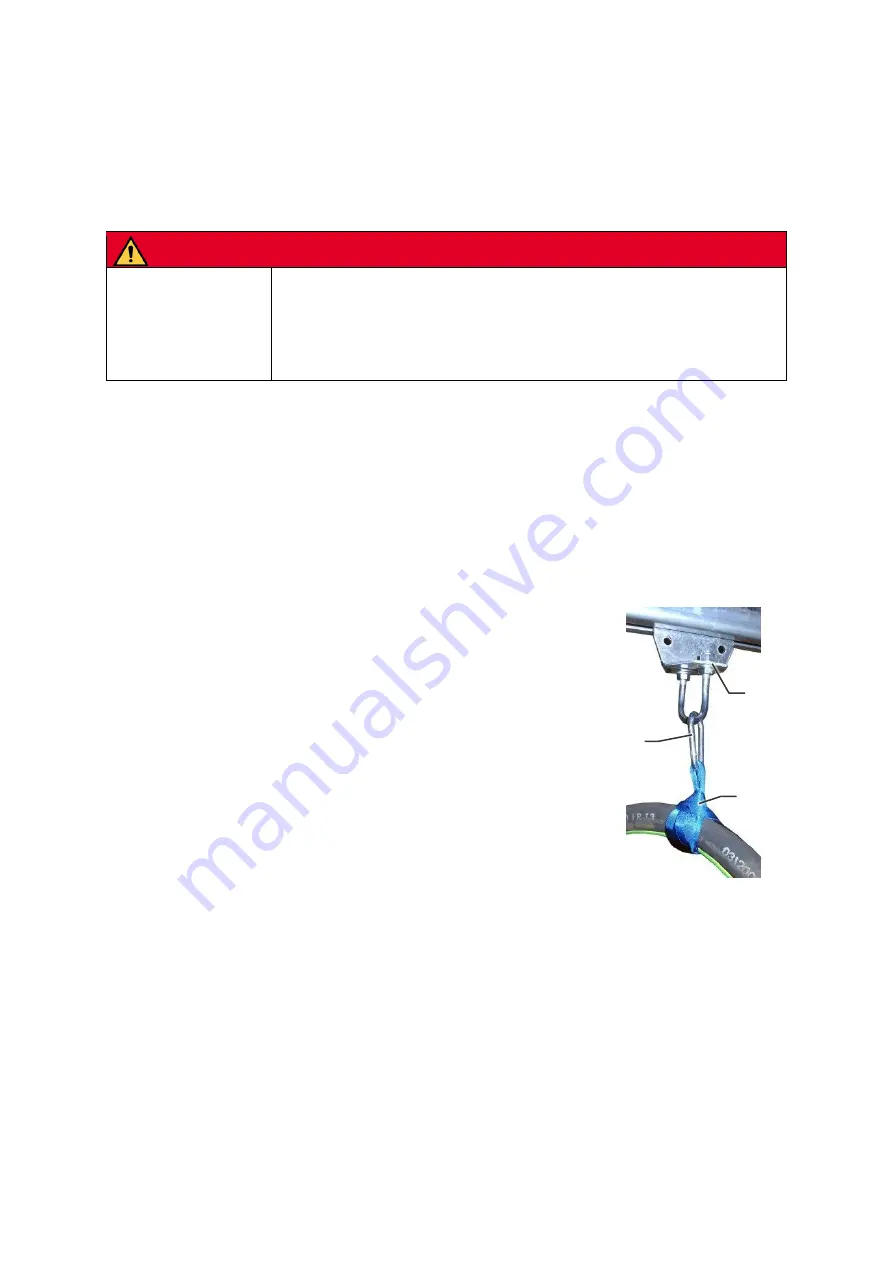

2. Connect compressed air hose (2) to compressed air

connection on ejector and secure this using hose clamp.

3. Lay hose assembly out in a coil of around 80 cm in diameter.

4. Attach first suspension band (3.2) like a loop about 1.2 m from

end of hose.

5. Attach remaining bands after each complete circle of hose

coil.

6. Insert carrier unit (10) into crane rails.

7. Pull karabiner hook (3.1) to suspension band loop (3.2) and

attach to transport trolley (3) and/or securing clamp (10.1).

8. Connect other side of compressed air hose to compressed air

supply at point of installation using a hose clamp or any other

suitable connection device.

9. Lay grounding line parallel to compressed air hose.

10. Connect compressed air hose (2) and grounding line using

cable ties (one cable tie approx. every 30 cm).

10

3.2

3.1