Decommissioning and recycling

EN-US · 30.30.01.01598 · 02 · 01/18

71 / 74

13 Decommissioning and recycling

13.1 Disposing of the Compact Terminal

1. Dispose of the product properly after replacement or decommissioning.

2. Observe the country-specific guidelines and legal obligations for waste prevention and disposal.

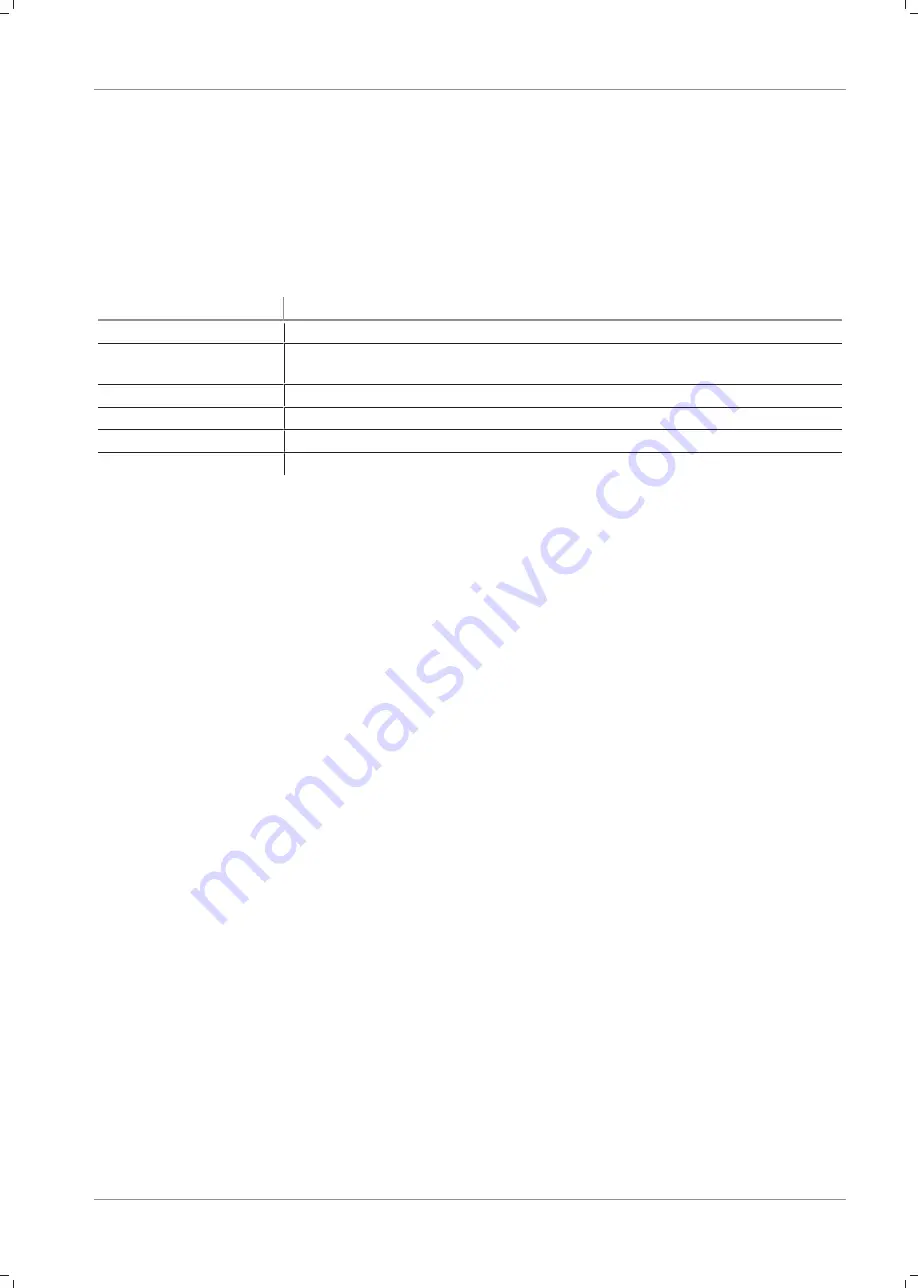

13.2 Materials Used

Component

Material

Housing

PA6-GF, PC-ABS

Inner components

Aluminum alloy, anodized aluminum alloy, brass, galvanized steel, stainless-

steel, PU, POM

Silencer insert

Porous PE

Screws

Galvanized steel

Sealing

Nitrile rubber (NBR)

Lubrication

Silicone-free