Operating Manual

V

ACU

M

ASTER

Multi-Serie

Chapter 4

Installation

J. Schmalz GmbH

Aacher Straße 29

D - 72293 Glatten

Tel +49 +7443 / 2403 - 0

Fax +49 +7443 / 2403 - 259

http://www.schmalz.de

e-mail: schmalz@schmalz.de

BA 30.30.01.00221-00

Status 03.2013

Page 11/18

4

Installation

4.1 General

The device must be installed and maintained by qualified personnel, mechanics

and electricians. Any work on the electrical equipment may be carried out only by a

qualified electrician.

.

Danger

The electrical connection must be made behind the disconnecting switch or

maintenance switch and in front of the main switch or emergency-stop

switch of the crane. When the main switch of the crane or the emergency-

stop switch are activated, the lifting unit must not switch off as this may be

dangerous

Installation

Suspend the lifting device from the suspension eye bolt on the crane or hoist

used. Fasten it safely! Observe the weight of the lifting device and the

maximum carrying capacity!

Pull the supply cable with plug from the control box. Connect the cable to the

power supply of the crane or hoist according to local regulations.

This job must be done by a qualified electrician.

Be sure, that the power supply is switched off!

Check rotation

direction

Before starting operation you have to check the rotation direction of the blower:

Switch on the blower.

Watch the fan of the blower motor. It must turn in the direction indicated by the

arrow on the motor housing.

If it rotates in the opposite direction, transpose the power connection of the

supply line.

Recheck the rotation direction.

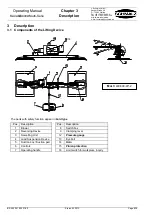

4.2 Adjusting the Load

Suspension Device

The load suspension device is firmly screwed to the unit’s body.

Before starting operation check the screwed connections for proper fixing.

To alter the adjustments loosen the star-grip handles (2) / clamping lever (3) on the

glide shoes by one revolution. Adjust the rail or suction box to the desired position

and retighten the star-grip handle / clamping lever.

Be sure the load suspension device is adjusted symmetrically. Thereafter check

the vacuum connections (hoses).

All types except Multi 400/300-90°-8

Multi 400/300-90°-8

1

2

1

2

3