3

EN

AES 2355/2356; AES 2555/2556

AES 2365/2366; AES 2565/2566

Operating instructions

Safety-monitoring module

2.5

Safety classiication

Standards:

EN ISO 13849-1; IEC 61508

PL:

up to d

Control category:

up to 3

PFH value:

1.0 x 10

-7

/ h; applicable for

applications with up to max.

50,000 switching cycles / year

and max. 80 % contact load.

Diverging applications upon request.

SIL:

up to 2

Service life:

20 years

3 Mounting

3.1 General mounting instructions

Mounting: snaps onto standard DIN rails to EN 60715.

3.2 Dimensions

Device dimensions (H/W/D): 100 x 45 x 121 mm

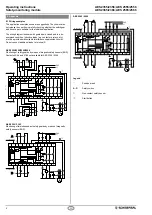

4 Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

Wiring examples: see appendix

5 Operating principle and settings

AES 2355/2356 and AES 2555/2556

Monitoring of two safety switches, which are simultaneously actuated

by a safety guard (e.g. safety guard, diversitary actuation). Monitoring

of one or multiple safety guards in series-/parallel-wiring only possible

with a AES 2355/2356 and AES 2555/2556 series safety-monitoring

module. The number of connected safety switches is restricted by the

contract transition resistance and the conduction resistance. This

overall resistance must not exceed 300 Ω. For magnetic safety sensors

with LED, the brightness of the LED's reduce as the amount of guard

doors opened increases.

AES 2365/2366 and AES 2565/2566

Monitoring of safety switches, which are actuated by different safety

guards (e.g. two guard doors, which are opened independently from

one another).

Operating principle after the operating voltage is switched on

Without start-up test AES 2355 / 2555 / 2365 / 2565

1. The function of the safety-monitoring module is tested.

2. If the safety guard is closed, the enabling path of the safety-

monitoring module will close. The LED is green.

3. The cable and the connected safety switch are only tested when the

safety guard is opened or the emergency stop button when actuated.

With start-up test AES 2356 / 2556 / 2366 / 2566

1. The function of the safety-monitoring module is tested.

2. The safety guard must be actuated, in order to check the cables and

the connected safety switch (start-up test).

3. If the safety guard is closed, the enabling path of the safety-

monitoring module will close. The LED is green.

If the safety guard is opened, the enabling path of the safety-monitoring

module will open.The machine is stopped and the LED lashes yellow.

This contact however must not be integrated in the safety circuit.

Inputs S1-S14/S22; S2-S14/S22

Safety switches with one NC and one NO contact must be connected

to the inputs S1/S2.

Feedback circuit X1/X2

Connect the feedback circuit of the external contactor with positive

action contacts and/or a start button to the inputs X1 and X2 or bridge

the inputs X1 and X2.

Enable delay time X7/X8

By bridging the connections X7/X8, the enable delay time (i.e. time

during which after the irst closing of the guard, bouncing of the switch

contacts or of the entire guard is possible without error message) can

be extended from 0.1 s to 1 s. The enable delay time simultaneously

is the minimum time, expiring between the guard being closed and the

relays being activated.

Outputs

Enabling paths 13-14, 23-24, 33-34, (43-44)

NO contacts for safety functions

Additional contact 51-52

NC contact for signalling purposes

Additional outputs Y1/Y2

Y1: indication "guard open"

Y2: indication "error"

The additional outputs Y1 and Y2 must not be integrated in the safety

circuit; they may only be used for signalling purposes.

6 Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct itting of the safety-monitoring module

2. Fitting and integrity of the power cable

6.2 Maintenance

In the case of correct installation and adequate use, the safety-

monitoring module features maintenance-free functionality.

A regular visual inspection and functional test, including the following

steps, is recommended:

• Check the correct ixing of the safety monitoring module

• Check the cable for damage.

Damaged or defective components must be replaced.

7 Disassembly and disposal

7.1 Disassembly

The safety monitoring module must be disassembled in the de-

energised condition only.

7.2 Disposal

The safety monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.