2

Operating instructions

Solenoid interlock

AZM 170 I

EN

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

AZM 170

➀

-

➁

Z

➂

I

➃

-

➄

-

➅

-

➆

➇

No. Option

Description

➀

Cut clamps

SK

Screw connection

➁

11

1 NO / 1 NC

02

2 NC

➂

Latching force 5 N

R

Latching force 30 N

➃

Power to unlock

A

Power to lock

➄

Cable gland

ST

M12 x 1 connector

ST-2431

M12 connector, separated magnet monitoring

➅

B1

Actuator B1 included

B5

Actuator B5 included

B6L

Actuator B6L included

B6R

Actuator B6R included

➆

Manual release

2197

Manual release from side (default in the

connector and power-to-unlock version)

1637

Gold-plated contacts

➇

24 VAC / DC U

s

24 VAC / DC

110 VAC

U

s

110 VAC

230 VAC

U

s

230 VAC

AZM 170

➀

-

➁

Z

➂

I

➃➄

-

➅

-

➆

24 VAC / DC

No. Option

Description

➀

SK

Screw connection

ST

M12 x 1 connector

➁

12 / 11

1 NO 2 NC / 1 NO 1 NC

12 / 02

1 NO 2 NC / 2 NC

12 / 00

1 NO 2 NC / -

11 / 11

1 NO 1 NC / 1 NO 1 NC

11 / 02

1 NO 1 NC / 2 NC

02 / 10

2 NC / 1 NO

02 / 01

2 NC / 1 NC

➂

Latching force 5 N

R

Latching force 30 N

➃

Power to unlock

A

Power to lock

➄

B1

Actuator B1 included

B5

Actuator B5 included

B6L

Actuator B6L included

B6R

Actuator B6R included

➅

1637

Gold-plated contacts

➆

2197

Manual release for Power to unlock

Only if the information described in this operating instructions

manual are realised correctly, the safety function and therefore

the compliance with the Machinery Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Destination and use

The solenoid interlock has been designed to prevent in conjunction

with the control part of a machine, movable safety guards from being

opened before hazardous conditions have been eliminated. The

AZM 170 I solenoid interlocks with individual coding offer a higher

protection against tampering.

Interlocks with the power to lock principle may only be used

in special cases after a thorough evaluation of the accident

risk, since the guarding device can immediately be opened

on failure of the electrical power supply or when the main

switch is opened.

The safety switchgear units are classified as type 2

interlocking devices in accordance with ISO 14119 and

are rated as highly coded.

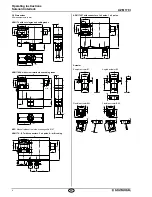

Manual release

A manual release is available as a mounting tool and in the event of

a power failure in case the power to unlock principle is used. If the

triangular key is turned 180°, the locking bolt is pulled into the unlocking

position. Please ensure that jamming by external influence on the

actuator is avoided. The normal locking function is only restored after

the triangular key has been returned to its original position. After being

put into operation, the manual release must be secured by installing the

sealing plug, which is included in delivery.

Manual release

Manual release from side

Ordering suffix -2197 or ST

Triangular key TK-M5 (101100887) available as accessory.

Emergency exit

Fitting and actuation only from within the hazardous area.

To activate the emergency exit, turn the red lever in the direction of the

arrow to the end stop. Please ensure that jamming by external influence

on the actuator is avoided.

The user must evaluate and design the safety chain in

accordance with the relevant standards and the required

safety level.

The entire concept of the control system, in which the safety

component is integrated, must be validated to the relevant

standards.