5

AZM 170 I

Operating instructions

Solenoid interlock

EN

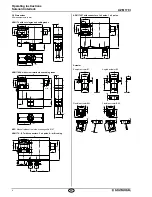

Mounting of the actuator

The marks on the used actuator opening of the solenoid

interlock and on the actuator must be opposite.

Please observe that, when fixing the switch e.g. by means of rivetting

or welding, the insertion depth of the actuator is not modified. Different

actuator forms are available. The actuators B1 and B5 are preferably

used for sliding and removable safety guards. For hinged guards, the

B6R and B6L actuators.

When the switch is fitted on a hinged safety guard, please ensure that

the point of rotation is located within the range of the upper surface of

the safety switch, in which the actuator hook is inserted (refer to table).

Actuating radii

d

R min.

d

R min.

R

min

[mm]

d

[mm]

R

min

[mm]

d

[mm]

B6L

50

11

50

11

B6R

50

11

50

11

B1

–

–

–

–

B5

–

–

–

–

Key

d

d

R min.

R min.

Actuating radius over the small edge of the actuator

d

d

R min.

R min.

Actuating radius over the wide edge of the actuator

The axis of the hinge must be d mm above and in a parallel plane to the

top surface of the safety switch. The basis setting provides a minimum

radius of Rmin.

Actuator B6L / B6R

b

a

a

b

b

a

a

b

b

a

a

b

The B6L or B6R actuators are set to the smallest radius in factory. To

increase the radius, the setting screws a + b must be turned by means

of a hexagonal key A/F 2.5 mm.

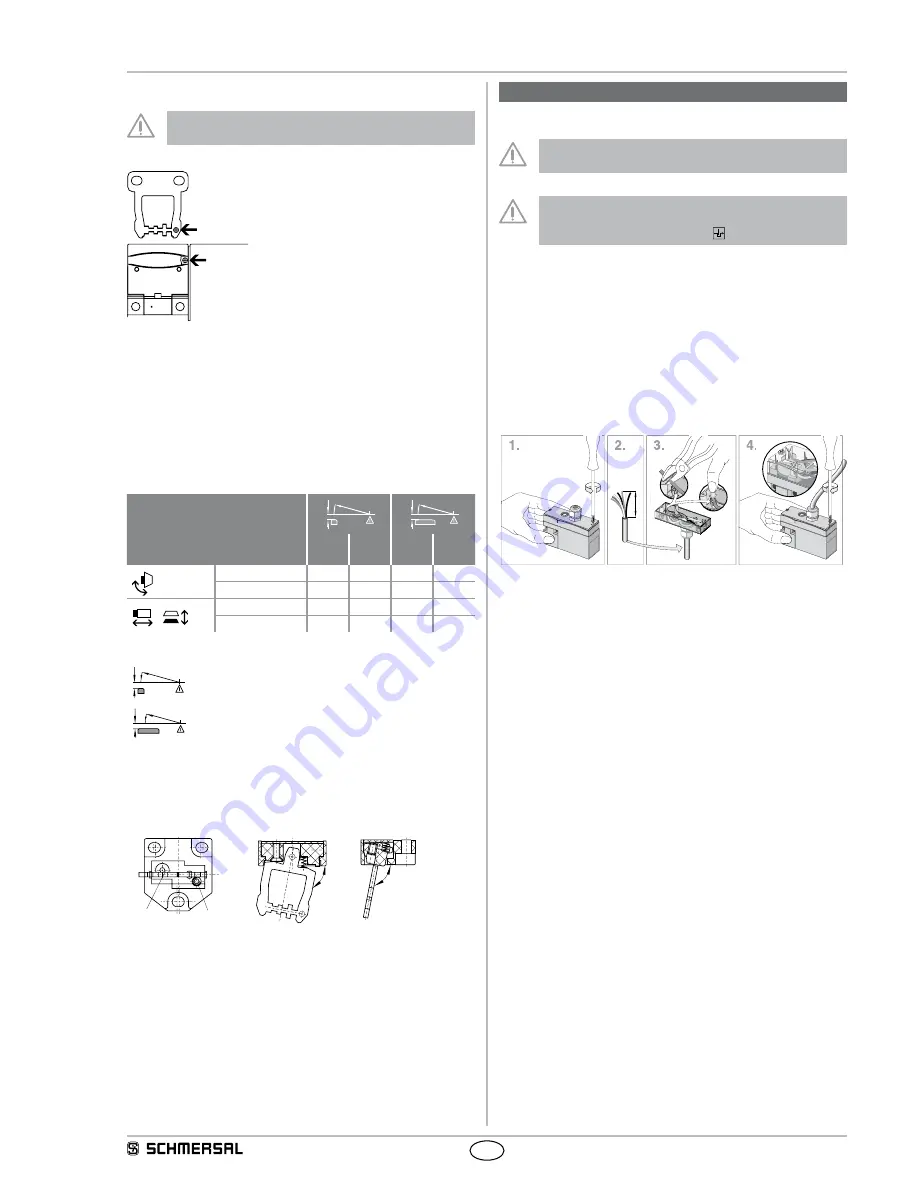

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

If the risk analysis indicates the use of a monitored interlock

they are to be connected in the safety circuit with the

contacts indicated with the symbol .

For the cable entry, suitable cable glands with an appropriate degree of

protection must be used.

Cut clamp terminals

The IDC method of termination (cut clamp technology) enables

connecting flexible wires with cable section 0.75 - 1 mm

2

without using

conductor ferrules. To this effect, strip the wire according to the drawing

(refer to the wiring example) and insert it into the cable gland, close the

cable gland, push the conductors in the groove of the cover (refer to

wiring example) and screw the cover back. Observe that the individual

conductors remain in position to avoid jamming.

70

mm

Screw terminals (SK version)

Unscrew the cover of the enclosure. Connect the cables to the terminal

block. Use insulated conductor ferrules to that effect. Screw the cover

back on the enclosure.