7

AZM 170 I

Operating instructions

Solenoid interlock

EN

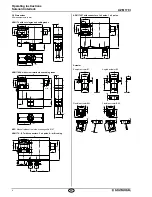

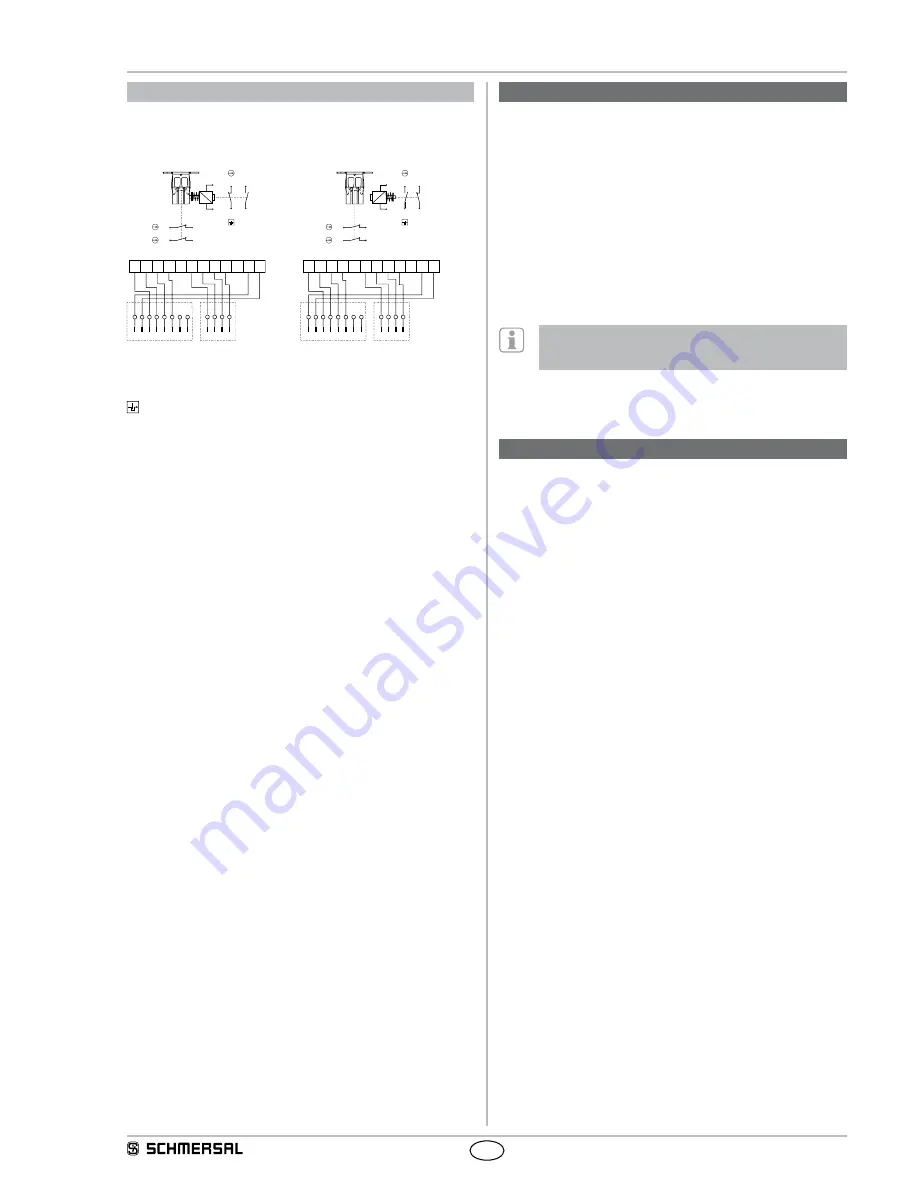

AZM 170 I with connector

Power to unlock

Power to lock

1 NO 1 NC / 2 NC

(ordering suffix -11/02)

1 NO 1 NC / 2 NC

(ordering suffix -11/02)

11

13

14

12

A1

41

31

32

42

A2

31

41 42

32

A1 A2

1 2 3 4

13

11 12

14

1 2 3 4 5 6 7 8

31

41 42

32

A1 A2

1 2 3 4

13

11 12

14

1 2 3 4 5 6 7 8

A1

11

13

14

12

41

31

32

42

A2

Key

A

Positive break NC contact

Monitoring the interlock according to ISO 14119

5. Set-up and maintenance

5.1 Functional testing

The safety function of the safety components must be tested. The

following conditions must be previously checked and met:

1. Fitting of the solenoid interlock and the actuator

2. Check the integrity of the cable entry and connections

3. Check the switch enclosure for damage

5.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check for tight installation of the actuator and the switch

2. Remove particles of dust and soiling

3. Check cable entry and connections

Adequate measures must be taken to ensure protection

against tampering either to prevent tampering of the safety

guard, for instance by means of replacement actuators.

Damaged or defective components must be replaced.

6. Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

6.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.