16

Operating instructions

Solenoid interlock

AZM201

EN

2.6 Safety classification

- of the interlocking function

Standards:

ISO 13849-1, IEC 61508, IEC 62061

PL:

e

Control Category:

4

PFH:

1.9 x 10

-9

/ h

PFD:

1.6 x 10

-4

SIL:

suitable for SIL 3 applications

Mission time:

20 years

- of the guard locking function

Standards:

ISO 13849-1, IEC 61508, IEC 62061

PL:

d

Control Category:

2

PFH:

1.0 x 10

-8

/ h

PFD:

8.9 x 10

-4

SIL:

suitable for SIL 2 applications

Mission time:

20 years

The safety consideration of the guard locking function

only applies for standard devices with monitored solenoid

interlock AZM201Z-…-1P2PW-… (see Ordering code).

A safety assessment of the guard locking function for

devices with serial diagnostics "SD2P" is not allowed due to

the non-safe locking/unlocking signal from the SD Gateway

The actuation of the interlock must be compared with the

external OSSD enabler. If a shut-down now occurs due to

an unintentional unlocking this is detected by an external

diagnostic.

If for a certain application the power to unlock version of a

solenoid interlock cannot be used, then for this exception an

interlock with power to lock can be used if additional safety

measure need to be realised that have an equivalent safety

level.

The safety analysis of the guard locking function refers to the

component solenoid interlock AZM as part of the complete

system.

On the customer side further measures such as safe

actuation and safe cable installation to prevent faults are to

be implemented.

In the event of a fault resulting in the unlocking of the guard

locking, this is detected by the solenoid interlock and the

safety gates Y1/Y2 switch off. When such a fault occurs

the protection equipment may open immediately, just once,

before the safe condition of the machine is reached. The

system reaction of category 2 allows that a fault can occur

between tests causing the loss of the safety function which is

detected by the test.

3. Mounting

3.1 General mounting instructions

Please observe the relevant requirements of the

standards ISO 12100, ISO 14119 and ISO 14120.

For fitting the solenoid interlock, two mounting holes for M6 screws

with washers (washers included in delivery) are provided. The solenoid

interlock must not be used as an end stop. Any mounting position.

The mounting position however must be chosen so that the ingress of

dirt and soiling in the used opening is avoided. The unused actuator

opening must be sealed by means of the dust-proof flap (included in

delivery).

Minimum distance between two solenoid interlocks

as well as other systems with same frequency (125 kHz): 100 mm.

Mounting of the solenoid interlock and the actuator

Refer to the mounting instructions manual for the corresponding

actuator.

The actuator must be permanently fitted to the safety guards

and protected against displacement by suitable measures

(tamperproof screws, gluing, drilling of the screw heads).

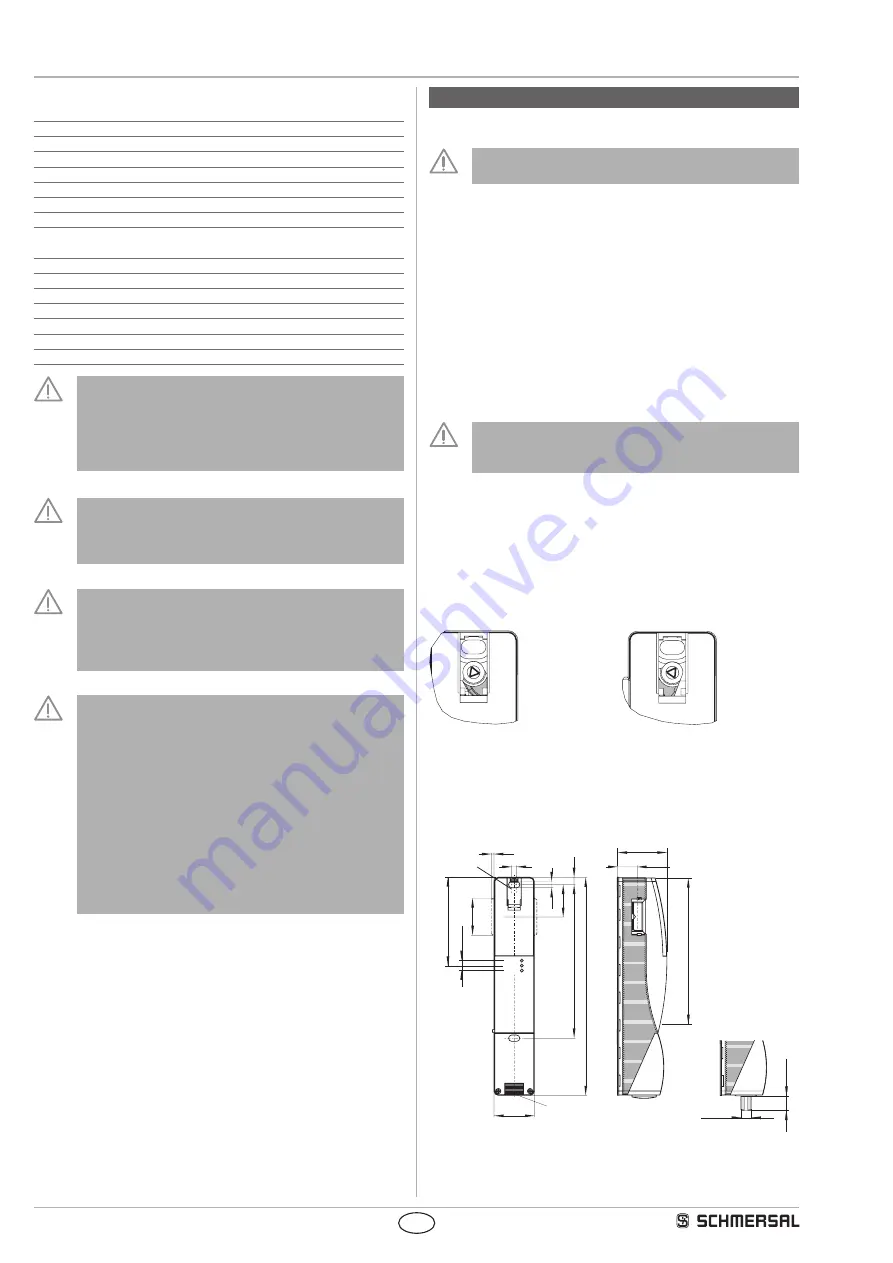

3.2 Manual release

For the machine set-up, the solenoid interlock can be unlocked in a de-

energised condition. After opening of the plastic flap "A" (refer to image

"Dimensions"), the triangular key must be turned clockwise to bring the

blocking bolt in unlocking condition. The normal locking function is only

restored after the triangular key has been returned to its original position.

Caution: do not turn beyond the latching point! After being put into

operation, the manual release must be secured by closing the plastic flap

"A" and affixing the seal, which is included in delivery.

Component ready

for operation

Component not ready

for operation

3.3 Dimensions

All measurements in mm.

40

220

155,5

5

6,5

32,5

38

7,5

M20x1,5

3,3

20 1

±

50

M12

Power

Fault

Status

150

(B)

15,5

13,3

89

A

Key

A: Manual release

B: Active RFID area