18

Operating instructions

Solenoid interlock

AZM201

EN

6. Diagnostic functions

6.1 Diagnostic-LEDs

The solenoid interlock signals the operational state as well as errors

through three coloured LED’s installed on the front side of the device.

green

(Power)

Supply voltage on

yellow

(Status)

Operating condition

red

(Fault)

Error (see table: Error messages /

flash codes red diagnostic LED)

6.2 Solenoid interlock with conventional diagnostic output

The short-circuit proof diagnostic output can be used for central

visualisation or control functions, e.g. in a PLC.

The diagnostic output is not a safety-related output.

Error

Errors, which no longer guarantee the function of the solenoid interlock

(internal errors) cause the safety outputs to be disabled immediately.

Any error that does not immediately affect the safe functionality of the

solenoid interlock (e.g. excess ambient temperature, safety output to

external potential, short circuit) will lead to a delayed shut-down (refer

to table 2).

After fault rectification, the sensor can be reset by opening and

relocking the relevant guard door. The safety outputs enable and allow

a restart. An interlocking chain must be permanently "locked" to enable

the reactivation.

Automatic, electronic locking takes place if more than one

fault is detected at the safety outputs or a cross circuit is

detected between Y1 and Y2. This means that normal fault

acknowledgement is no longer possible. To reset this type of

interlocking, the solenoid interlock must be isolated from the

power supply after elimination of the error causes.

Error warning

A fault has occurred, which causes the safety outputs to be disabled

after 30 minutes. The safety outputs initially remain enabled. This

signal combination, diagnostic output disabled and safety channels still

enabled, can be used to stop the production process in a controlled

manner. An error warning is deleted when the cause of error is

eliminated.

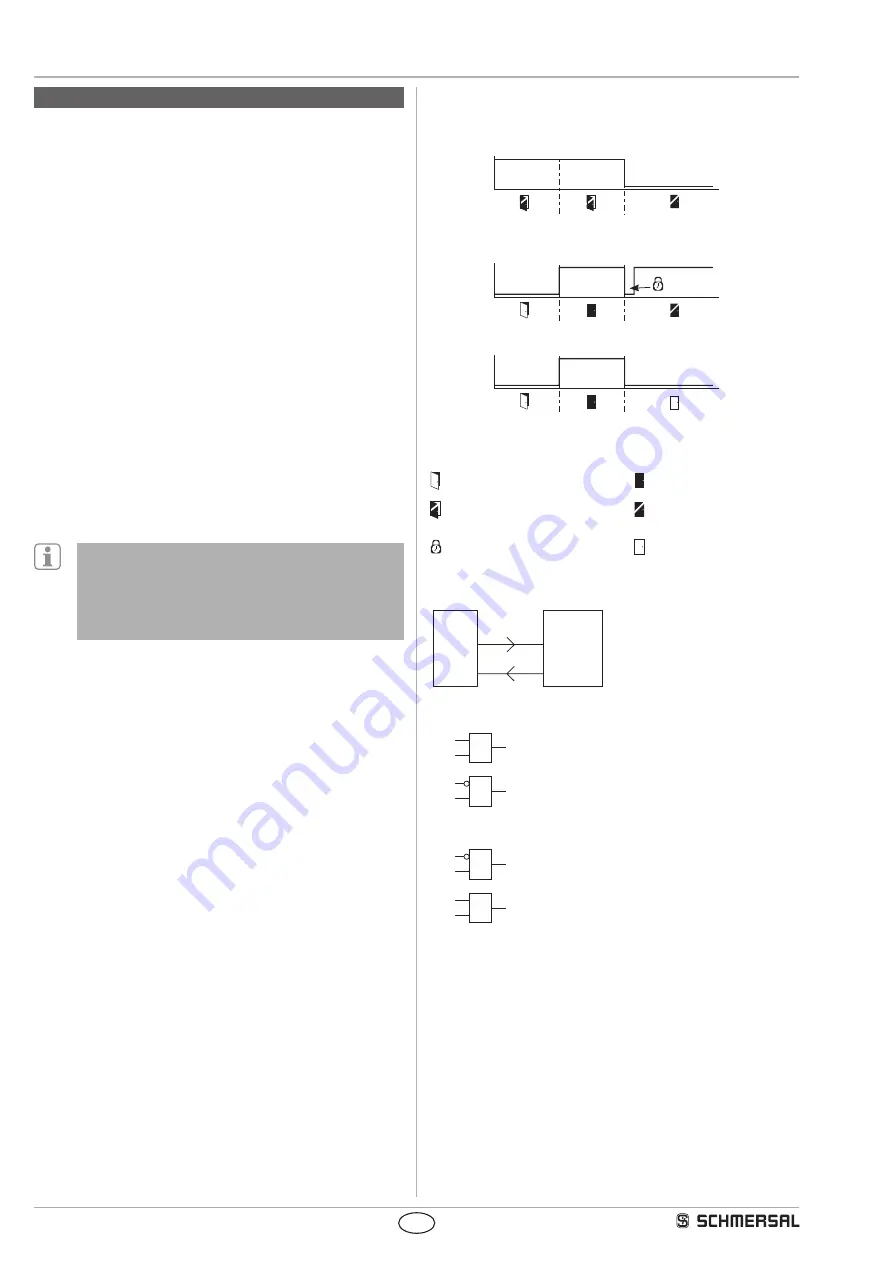

Behaviour of the diagnostic output (Version ...-1P2PW)

(Example: power to unlock version)

Input signal magnet control

IN

Normal sequence, door was locked

OUT

Door could not be locked or fault

OUT

Key

Safety guard open

Safety guard closed

Unlock safety guard

Safety guard locked

Locking time: 150 ... 250 ms,

typically 200 ms 250 ms,

typically 200 ms

Safety guard not locked or fault

Evaluation of the diagnostic output (Version ...-1P2PW)

SPS

SPS

AZM 200

AZM 200

I N

O U T

E 1 . 0

A 1 . 0

A 1 . 0

E 1 . 0

A 1 . 0

E 1 . 0

M 1 . 0

M 1 . 0

M 2 . 0

M 2 . 0

&

&

A 1 . 0

E 1 . 0

&

A 1 . 0

E 1 . 0

&

Door can be locked

Door can be locked

Power to unlock: IN = 0 = locking

Door is locked

Door is locked

Power to lock: IN = 1 = locking

AZM201