7

AZM400

Operating instructions

Solenoid interlock

EN

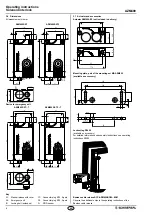

4. Rear side Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

The voltage inputs A1 (and H1 with the AZM400Z-ST2..), and the

control inputs E1, E2 and E3 must have a permanent protection against

over-voltage. The use of PELV supply units according to IEC 60204-1

is recommended. The safety outputs can be integrated into the safety

circuit of the control system.

4.2 Control options in the normal operating mode

Due to the control inputs E1, E2 and E3 for controlling the guard locking

function it is possible to use different control options to be able to drive

the AZM400 with a different safety controller. The function of the control

inputs is the same for both ST and ST2 versions.

Setting the operational control inputs according to the following table

causes the interlock to unlock.

Input condition

Version P/P

Version P/N

E1

E2

E3

E1 = E2

E3

Lock

open

open

GND

open

open

Unlock

24 V

24 V

GND

24 V

GND

Use of safety outputs of the type P/P:

Safety controller

AZM400

P2

N

E1 (2)

E2 (8)

E3 (6)

Inp 2

Inp 1

P1

GND

24 V

24 V

Use of safety controls of the type P/N:

Safety controller

AZM400

Inp 1

P

N

E1 (2)

E2 (8)

E3 (6)

Inp 2

GND

24 V

The outputs used for the control must correspond to the

Performance Level (PL) of the guard system.

To achieve the PL e the control must have tested outputs as

these are not tested by the AZM400.

Independent of the version used, the notes in the Operating

Instructions of the used controller should be observed.

These could include:

- Shielded installed cable

- Minimum test interval every 24 hours

- etc.

Block drive

If the locking bolt does not reach the "locked" condition with the first

attempt, the AZM400 makes an autonomous attempt. If the second

attempt also fails, the AZM400 signals a fault (comp. table 2).

After a malfunction, condition of the control inputs has to be changed to

allow the locking bolt to be driven out again.

When the guard system closes slowly, a block drive can occur if the

actuator that is opening is not in front of the bolt being driven out (see

Chapter "Operating equipment and distances").

Unlocking after Power On

If after switching on, the AZM400 is already in the locked position, the

device must first be unlocked and then locked again. This is to verify

the causality of the drive signals and to check the sufficient depth of

the locking bolt. The yellow LED flashes after power-on in the locked

position.

4.3 Requirements for the connected safety-monitoring module

• Dual-channel safety input, suitable for 2 p-type semi-conductor

outputs (OSSD)

The solenoid interlock cyclically switch off the safety output to test

them. The safety-monitoring module therefore does not need to be

equipped with a cross-wire short detection. The test impulse time of

≤ 0.4 ms must be tolerated by the evaluation. The test impulse, the

switch-off time of the solenoid interlock can be extended depending on

the cable length and the capacity of the cable used.

Configuration of the safety controller

If the solenoid interlock is connected to electronic safety-

monitoring modules, we recommend that you set a discrepancy

time of 100 ms. The safety inputs of the safety-monitoring

module must be able to blank a test impulse of < 1 ms.

Information for the selection of suitable safety-monitoring

modules can be found in the Schmersal catalogues or in the

online catalogue on the Internet: www.schmersal.net.