3

EDR EFR

Operating instructions

Emergency stop command device

EN

3 Mounting

3.1 General mounting instructions

•

Fit the EDR EFR emergency stop actuator in non-actuated

condition by means of the EFM mounting flange, align and tighten

(max. 0.6 Nm).

•

Snap the EFR spring element in the middle position of the EFM

mounting flange (position 3). The EFR spring element is supplied

in tensioned condition.

• The EDRR EFR actuator is latched, i.e. mechanically fixed, to the EFR

spring element by actuation. By rotating to the right and consecutive

pulling, the spring element is retensioned and the emergency stop

command device is brought back to its basic position.

• Snap the EF contact element(s) into position(s) 1 (and/or 2) of the

EFM mounting flange.

• EFR spring element: to avoid fitting errors, we recommend to fit

the enclosed locking plate (A) by means of both locking rings

(B) 4 mbo 09 after the contacts have been snapped on (see photo).

No special tools are required. This locking plate ensures a proper

fitting and fixation of the contact elements.

B

A

•

The emergency stop device is now ready for operation.

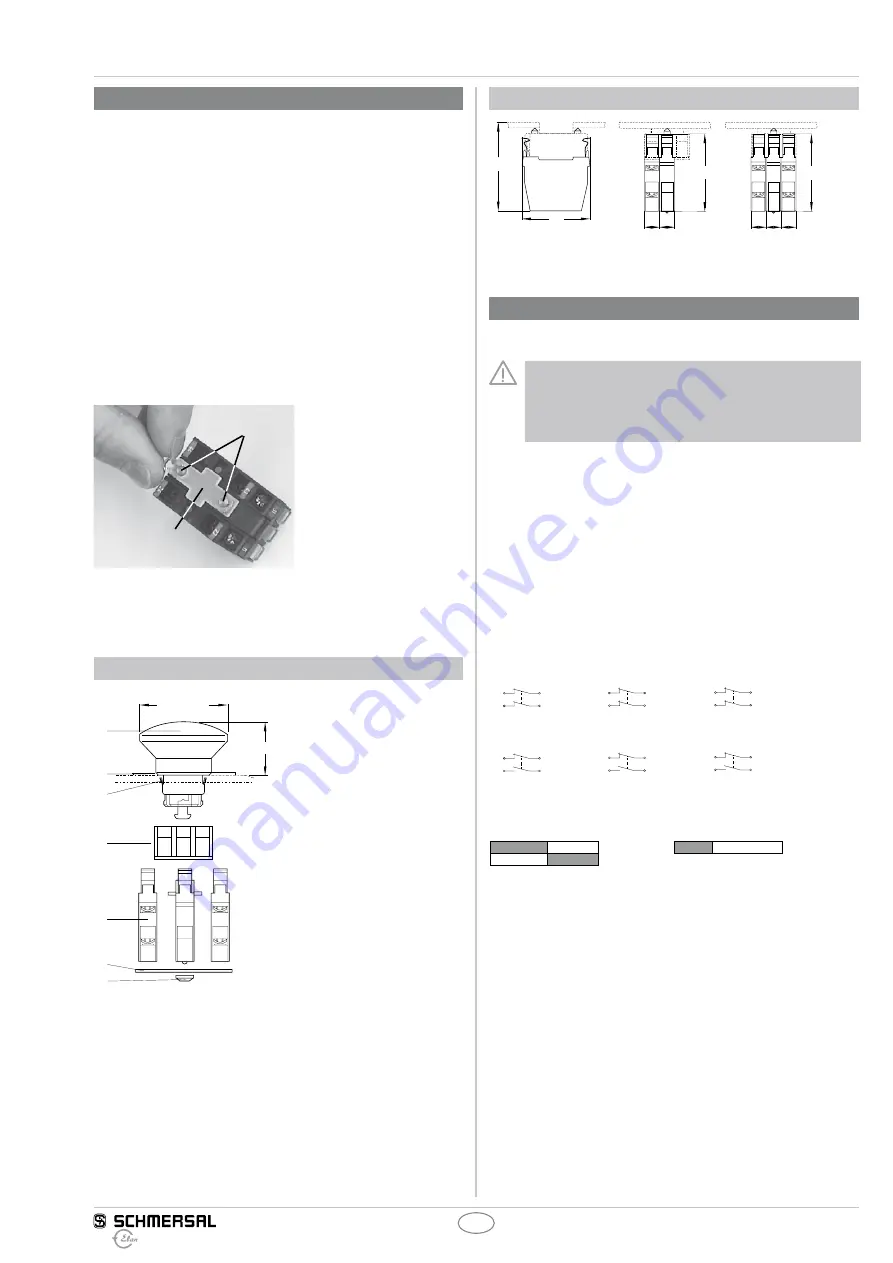

3.2 Dimensions

Dimensions of the EDRR emergency stop command device

Ø 49 (Ø 38,5)

29

a)

b)

c)

d)

e)

f)

g)

1

3

2

a) EDRR. emergency stop actuator

b) Emergency stop label

c) Clamping element

d) ELM mounting flange

e) 2 x EF contact element (Pos. 1 + 2),

1 x EFR spring element (middle, Pos. 3)

f) Locking plate

g) Locking rings 4 mbo 09

Dimensions of the EF contact elements in fitted condition

46

10

10

a)

EFR

EFR

52

52

10 10

10

60

a) Maximum number of contacts (2 contact elements, max. 4 contacts)

4 Electrical connection

4.1 Important notes

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

At least one contact with positive break must be integrated

in the safety circuit.

After wiring, the contact elements must be cleaned (i.e. remove

excess cables etc.).

The fixing screws of the contact element must be tightened with

0.8 Nm tightening torque.

4.2 Contact variants

The following contact combinations may be used:

•

Screw or plug-in terminals:

– 1 × EF 303 (1 NC/1 NO contact) + 1 × EF 220 (2 NC contacts) or

– 2 × EF 303 (1 NC/1 NO contact) or

•

EFK cage clamp: contact data upon request

11

21

EF 220.1

12

22

11

23

EF 303.1

12

24

31

41

EF 220.2

32

42

31

43

EF 303.2

32

44

51

61

EF 220.3

52

62

51

63

EF 303.3

52

64

4.3 Switch travel

0

6

3

3

0

6

2

EF 303.1/.2/.3

EF 220.1/.2/.3