8

Operating instructions

Solenoid interlock

MZM 100

MZM 100 B

EN

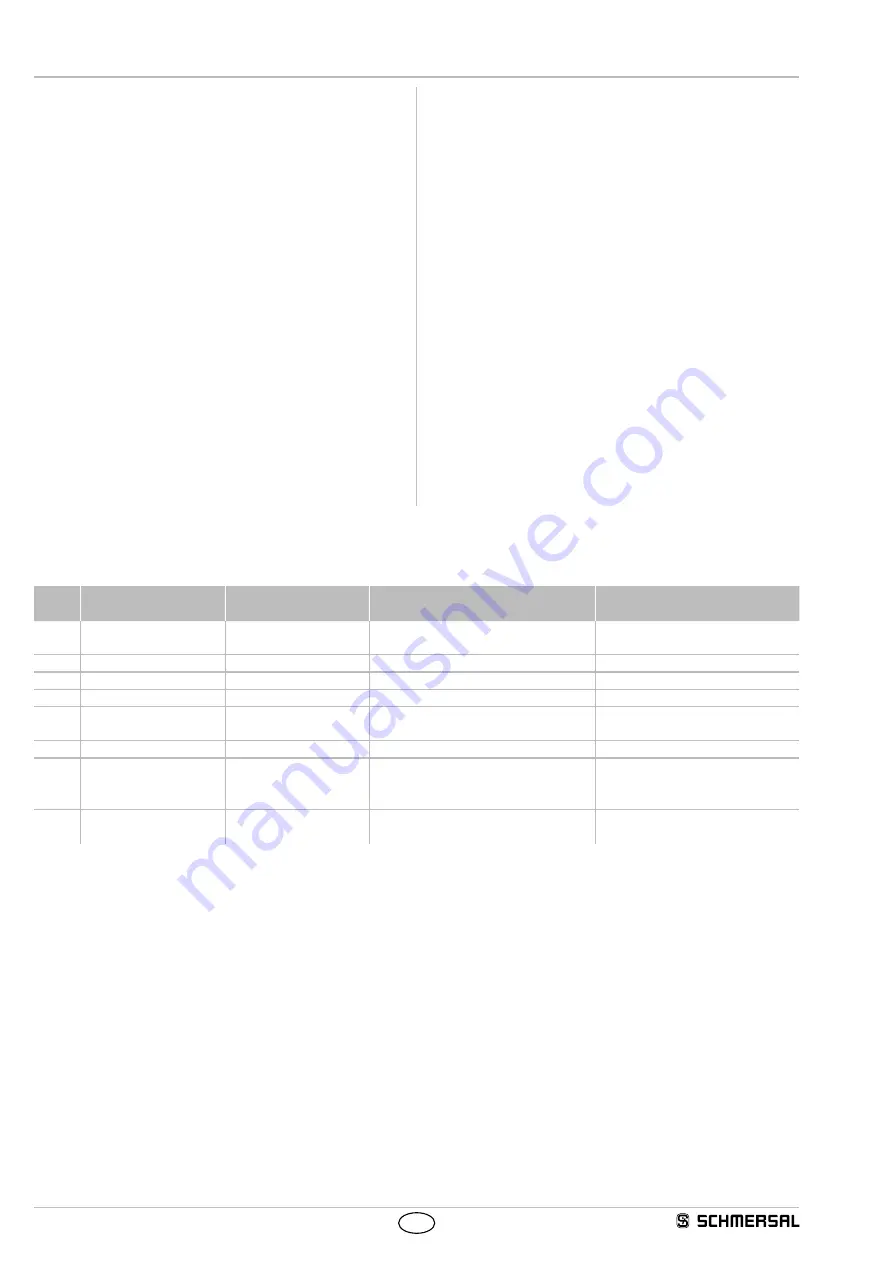

Table 3: I/O data and diagnostic data

Communication directions:

request byte: from the PLC to the local electronic safety switchgear response byte: from the local electronic safety

switchgear to the PLC warning/error byte: from the local electronic safety switchgear to the PLC

Bit n° Request byte

Response byte

Diagnostic

Error warning

Diagnostic

Error

Bit 0:

Magnet in,

error reset

Safety output

activated

Error output Y1

Error output Y1

Bit 1:

Latching force bit

Actuator detected

Error output Y2

Error output Y2

Bit 2:

Latching force bit

Solenoid interlock locked Cross-wire short

Cross-wire short

Bit 3:

Latching force bit

---

Magnet temperature too high

Magnet temperature too high

Bit 4:

---

Input condition

X1 and X2

Locking blocked or

F < 500 N

incorrect or defective actuator

Bit 5:

---

---

Internal device error

Internal device error

Bit 6:

---

Error warning

Communication error between the field

bus Gateway and the safety switchgear

Violent separation of actuator and

solenoid interlock (only in connection

with "Solenoid interlock monitored")

Bit 7:

Error reset

Error (enabling path

switched off)

Operating voltage too low

Operating voltage too low

The described condition is reached, when Bit = 1

6.3 Solenoid interlock with serial diagnostic function

Solenoid interlocks with serial diagnostic function have a serial input

and output instead of the conventional diagnostic output If SD devices

are wired in series, the safety channels as well as the inputs and

outputs of the diagnostic channels are wired in series The diagnostic

data are transmitted through the series-wiring of the inputs and outputs

Max 31 safety switchgear with serial diagnostics can be wired in series

For the evaluation of the serial diagnostics line either the PROFIBUS-

Gateway SD-I-DP-V0-2 or the Universal-Gateway SD-I-U- are used

This SD-Gateway is integrated as a slave in an existing field bus

system In this way, the diagnostic signals can be evaluated by means

of a PLC The necessary software for the integration of the

SD-Gateway is available for download at wwwschmersalnet

The response data and the diagnostic data are automatically and

permanently written in an input byte of the PLC for each safety device

in the series-wired chain The request data for each safety device is

transmitted to the component through an output byte of the PLC

In case of a communication error between the SD-gateway and the

safety device, the switching condition of the solenoid interlock is

maintained

Error

A fault has occurred, which causes the safety outputs to be disabled

The fault is reset, when the cause is eliminated and bit 7 of the request

byte changes from 1 to 0 or the safety guard is opened Faults at the

safety outputs are only deleted upon the next release, as the fault

rectification cannot be detected sooner

Error warning

A fault has occurred, which causes the safety outputs to be disabled

after 30 minutes The safety outputs initially remain enabled

This enables the shutdown of the process in a controlled manner

An error warning is deleted when the cause of error is eliminated

Diagnostic error (warning)

If an error (warning) is signalled in the response byte, detailed fault

information can be read out