4

Operating instructions

Input expander module

PROTECT-IE

EN

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct fixing of the input expander module

2. Check the cable for damages

3. Check electrical function

The device has to be integrated into the periodic check-ups

according to the Ordinance on Industrial Safety and Health,

however at least 1x/year.

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

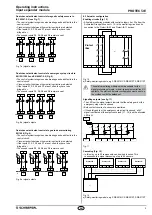

The input expander module must be disassembled in the

de-energised condition only.

Insert a screwdriver at the marked position, press in the direction of the

cover and remove.

2)

1)

61*

53**

Fig. 6:

1) Disassembly;

2) DIN rail system to EN 60715;

* with cage clamps;

** with plug-in terminals (representation of the standard version

PROTECT-IE-11)

7.2 Disposal

The input expander module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

8. Appendix

8.1 Wiring examples

• Start level: Depends on the wiring of the safety relay module

• Sensor level: Dual-channel control of magnetic safety sensors to

IEC 60947-5-3

• Output level: dual-channel control of a downstream safety-monitoring

module

F1

S1

–

S2

S3

A2

A2

Y4

+

A1

K7

K8

K5

K6

K3

K4

K1

K1

K2

K2

14

24

S6

13

23

A1

+

–

S4

+

S5

–

Y3

UB

+

S7

–

S8

Y1

Y2

K1/K2

K3/K4

K5/K6

K7/K8

K1

K3

K5

K7

K2

K4

K6

K8

Protect-IExx

S12

S11

S22

S21

14

13

24

23

a)

Fig. 3

a) Safety-monitoring module, e.g. SRB 301MC, SRB 301ST, SRB 211ST

8.2 Sensor configuration

Dual-channel control of magnetic safety sensors to IEC 60947-5-3

(see Fig. 4)

• The control system recognises wire breakage and earth faults in the

control circuit.

• Cross-wire shorts between the monitoring circuits are detected.

• If the inputs S1, S3, S5 and S7 are not used, they have to be

bridged to +.

• If the inputs S2, S4, S6 and S8 are not used, they have to be

bridged to –.

S1

+

S2

Y1

a)

–

S3

+

S4

Y2

–

S5

+

S6

Y3

–

S7

+

S8

Y4

–

Fig. 4 a) signal outputs

Dual-channel emergency stop circuit to EN ISO 13850 and

EN 60947-5-5 (Fig. 5)

• The control system recognises wire breakage and earth faults in the

control circuit.

• Cross-wire shorts between the monitoring circuits are detected.

• If the inputs S1, S3, S5 and S7 are not used, they have to be

bridged to +.

• If the inputs S2, S4, S6 and S8 are not used, they have to be

bridged to –.

S1

+

S2

Y1

a)

–

S3

+

S4

Y2

–

S5

+

S6

Y3

–

S7

+

S8

Y4

–

Fig. 5 a) signal outputs

Dual-channel guard door monitoring to EN 1088 (Fig. 6)

• The control system recognises wire breakage and earth faults in the

control circuit.

• Cross-wire shorts between the monitoring circuits are detected.

• If the inputs S1, S3, S5 and S7 are not used, they have to be

bridged to +.

• If the inputs S2, S4, S6 and S8 are not used, they have to be

bridged to –.

S1

+

S2

Y1

a)

–

S3

+

S4

Y2

–

S5

+

S6

Y3

–

S7

+

S8

Y4

–

Fig. 6 a) signal outputs