Installation manual

Page 162 of204

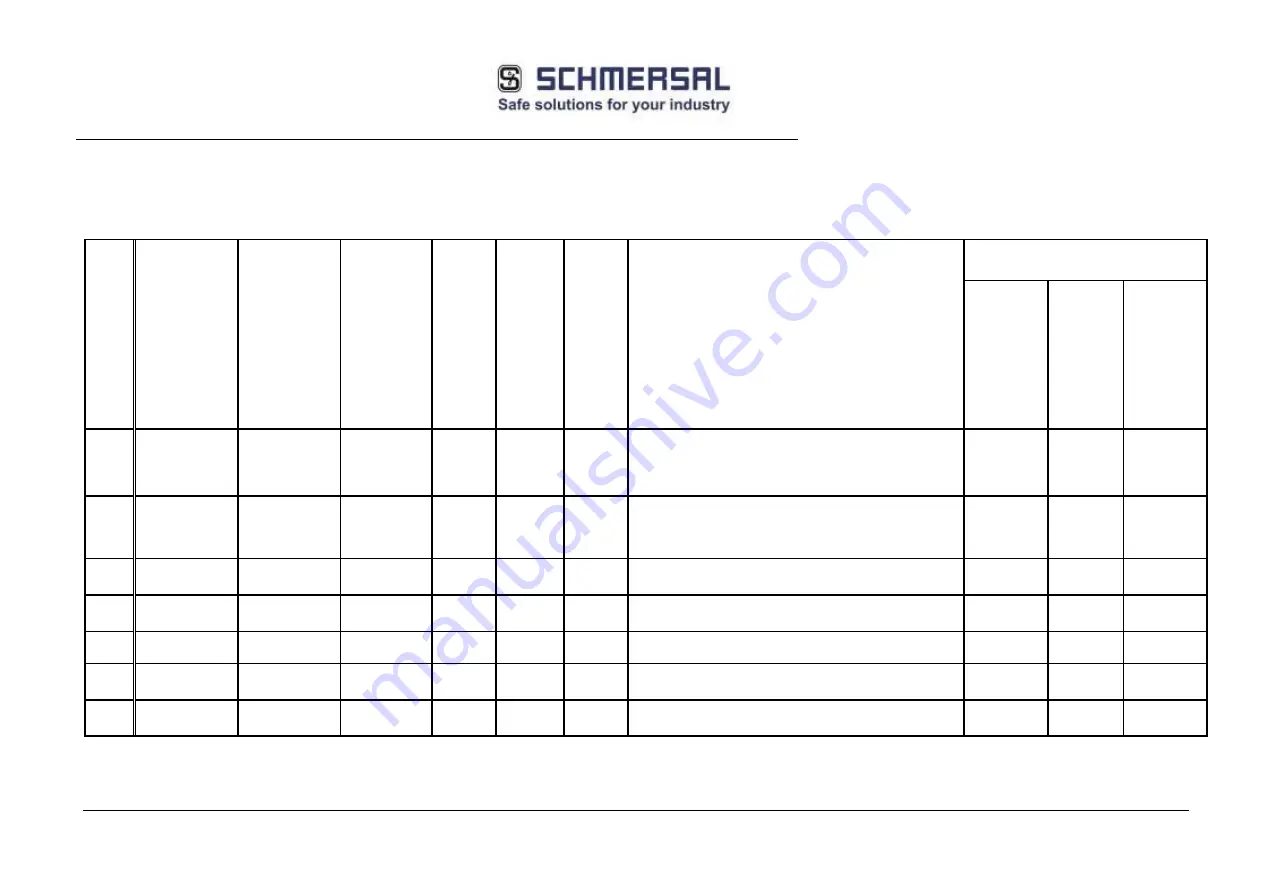

12 Encoder types

No.

Type

Encoder to

interface

X31/32

Type

Encoder to

interface

X31/34

Type

Encoder to

X 23

Safe

speed

Safe

direction

Safe

position

Fault exclusion

DC

1-channel

partial

system

2-channel

partial

system

dynamic

2-channel

partial

system

non-

dynamic

(standstill

monitoring)

69

NC

NC

1 x Bero

+

1 x Bero

X

Fault exclusion mech. shaft breakage, positive

encoder shaft connection required, if common

elements are in use.

n.a.

99%

80-90%

1

Incremental

NC

NC

X

Fault exclusion mech. shaft breakage, positive

encoder shaft connection required

60%

99%

80-90%

51

Incremental

Incremental

NC

X

X

n.a.

99%

95%

3

Incremental

NC

1 x Bero

X

n.a.

99%

90-95%

68

Incremental

NC

2 x Bero 90°

X

X

n.a.

99%

90-95%

62

Incremental

SIN/COS

NC

X

X

n.a.

99%

99%

54

Incremental

HTL

NC

X

X

n.a.

99%

90-95%

Summary of Contents for PSCBR-C-10 Series

Page 1: ...Installation manual Page 1 of204 Installation Manual For PSCBR modules Series PSCBR C 10...

Page 178: ...Installation manual Page 178 of 204...

Page 181: ...Installation manual Page 181 of 204 Example for a risk analysis Gefahrenanalyse Risk analysis...