7

SFB-PN-IRT-8M12-IOP-V2

Operating instructions

Safety fieldbox

EN

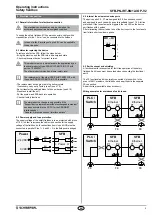

4.7 Connector configuration of device ports X0 – X7

Version: M12 socket, 8-pin, A-coded

PIN Colour* Signal Description of fieldbox signals

1

WH

A1

+ 24 VDC device supply

2

BN

Y1

Test pulse output 1,

safety channel 1 supply

3

GN

A2

0 VDC device supply

4

YE

X1

Safety input 1

5

GY

DI

Diagnostic-input / FB-Interface

6

PK

Y2

Test pulse output 2,

safety channel 2 supply

7

BU

X2

Safety input 2

8

RD

DO

Safe output

X4 – X7 additional with FB interface for BDF200-FB

The default setting is used for safety switchgear with

electronic OSSDs. If safety switchgear with dry contacts are

used, cross fault monitoring must be activated.

For safety switchgear with electronic OSSDs, cross fault

detection of the device connection cable must be carried

out by the safety switchgear.

4.8 Connector configuration POWER I/O

Version: M12 power connector/socket, 4-pin, T-coded

PIN Colour* Signal Description of fieldbox signals

1

BN

Us

+ 24 VDC SFB supply

(= PIN 4)

2

WH

GND

0 VDC SFB supply

(= PIN 3)

3

BU

GND

0 VDC SFB supply

(= PIN 2)

4

BK

Us

+ 24 VDC SFB supply

(= PIN 1)

4.9 Connector configuration PROFINET P1/P2

Version: M12 socket, 4-pin, D-coded

PIN Colour* Signal Description of fieldbox signals

1

YE

TD+

Transmit-Data +

2

WH

RD+

Receive-Data +

3

OG

TD-

Transmit-Data -

4

BU

RD-

Receive-Data -

Flange

FE

Ethernet shielding

* Colour code of SCHMERSAL M12 cables

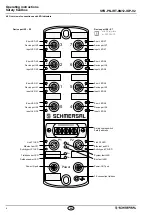

4.10

Setting the F-address and factory reset

Carefully remove the viewing window. (Screws Torx 10)

The screws of the viewing window are not secured.

Keep the screws safe so that they do not get lost.

Caution!

Electrostatically sensitive components.

Do not touch the printed circuit board directly.

When you open the inspection window, ensure that no

moisture or excessive humidity penetrates into the fieldbox.

The 3 rotary coding switches behind the viewing window can be used to

set the safety address and to carry out a factory reset of the SFB.

0 1

2

3

4

5

6

7

8

9

0 1

2

3

4

5

6

7

8

9

0 1

2

3

4

5

6

7

8

9

x 100

x 10

x 1

F address

1 - 999

Valid F address

0 - 0 - 0

Factory reset

Setting of the F address

• Remove power from the SFB

• Set the desired F address in the range 1 - 999

• Resupply power to the SFB

Carrying out an SFB factory reset:

• Remove power from the SFB

• Setting of F address 0 – 0 – 0

• Resupply power to the SFB

• After 15 seconds, switch off the power of the SFB-PN again

The IP address and the PROFINET name are deleted during a factory

reset.

5. Diagnostic functions

5.1 LED indicators, device ports X0 - X7

There are 2 LED indicators on each device port.

A green/red error LED and a yellow input LED to display the switching

condition at the safety inputs.

Error LED (E)

The error LED may exhibit the following display and flashing pattern:

LED display

Description

GREEN

ON

No fault at device port

GREEN

Flashes

Device port fault can be acknowledged

RED

1 impulse

Safety input cross-fault

RED

2 impulses Safety input fault

RED

3 impulses Test pulse output fault

RED

4 impulses Device supply overload

RED

5 impulses Digital output overload

RED

6 impulses Digital output fault

RED

7 impulses FB interface fault (only device ports 4-7)

Input LED (I)

The input LED may exhibit the following display and flashing pattern:

LED display

Description

YELLOW OFF

Both safety inputs LOW

YELLOW ON

Both safety inputs HIGH

YELLOW Flashes

Only one safety input HIGH,

or discrepancy/stable time fault