3

SLB 200

Operating instructions

Safety light barrier

EN

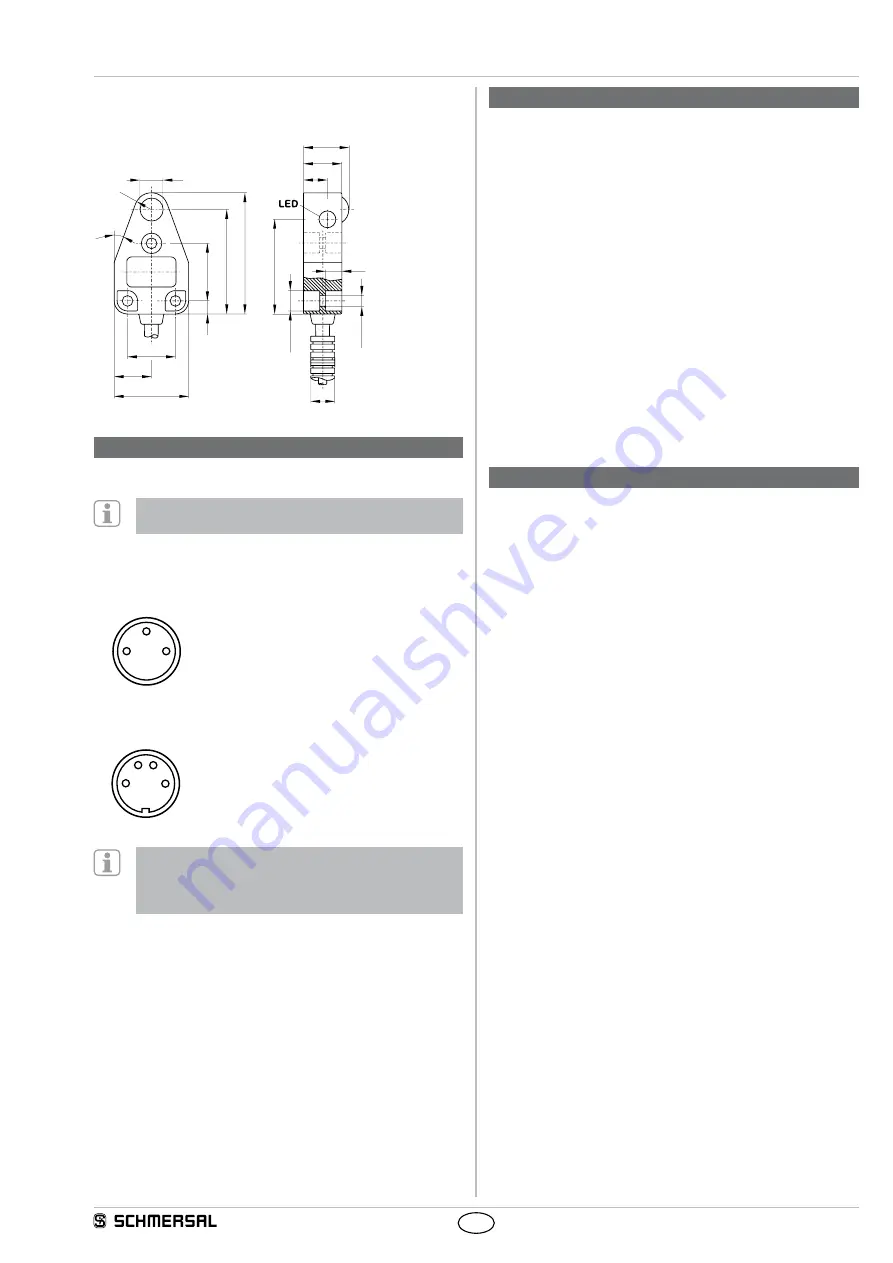

3.2 Dimensions

All measurements in mm.

9,6

R7

6,75

20°

18,8

30,8

39

,4

50

,3

4

3,

4

24

5,

5

15,5

20

16,1

10

ø

8,

5

(6

x)

ø4

,4

(3

x)

ø 10

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

Transmitter

SLB 200-E31-21

4

3

1

PIN

Description

1

BN

3

n.c.

4

WH

Receiver

SLB 200-R31-21

3

1

4

2

PIN

Description

1

BN

2

WH

3

n.c.

4

n.c.

Further information about the wiring and connection of

the safety light barrier to the safety-monitoring module

can be found in the operating instructions manual of the

SLB 200-C04-1R safety-monitoring module.

5. Set-up and maintenance

5.1 Functional testing

The safety function of the safety components must be tested. The

following conditions must be previously checked and met:

1. Correct fixing of the transmitter and receiver.

2. Fitting and integrity of the power cable.

3. If one or more light barriers are interrupted, the hazardous

movement is brought to standstill.

5.2 Maintenance

In the case of correct installation and adequate use, the safety switch-

gear features maintenance-free functionality. A regular visual inspection

and functional test, including the following steps, is recommended:

1. Check the correct mounting of the fixing screws on the safety

light barriers.

2. Clean the optics of transmitter and receiver with a soft clean cloth.

The use of agressive, abrasive or scratching cleaning agents,

which could attack the surface, is prohibited

Damaged or defective components must be replaced.

6. Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

6.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.