8

Operating instructions

Safety light barriers

SLB440

SLB450

EN

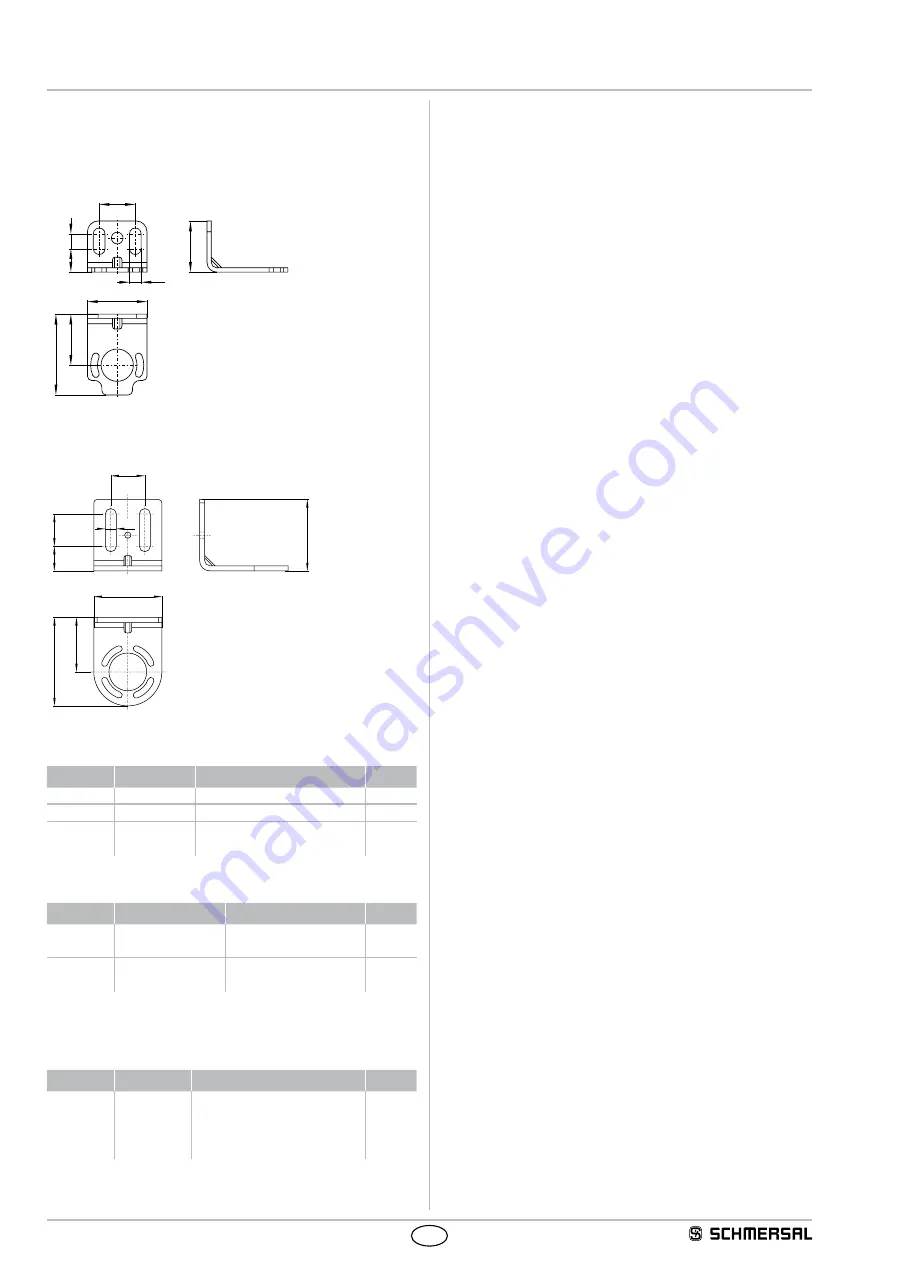

3.8 Mounting material (Not included in delivery!)

Mounting kit MS-1101 (only SLB440)

The mounting kit consists of 2 steel angles and 4 fixing screws (Type

Torx plus 10IP)

5,5

17

28

24

7

11

24

38

Mounting kit MS-1030 (only SLB450)

The mounting kit consists of 4 steel angles and 16 fixing screws

14,5

42

18,9

20

6,5

40

32

52

Connecting cable for emitter / receiver (4-pole)

Item N

o

Designation Description

Length

101207741 KA-0804

Female connector M12, 4-pole 5 m

101207742 KA-0805

Female connector M12, 4-pole 10 m

101207743 KA-0808

Female connector M12, 4-pole 20 m

Connecting cable for receiver (5-pole)*

Item N

o

Designation

Description

Length

101209949 A-K5P-M12-S-G-

5M-BK-2-X-A-1

Female connector M12,

5-pole

5 m

101209948 A-K5P-M12-S-G-

15M-BK-2-X-A-1

Female connector M12,

5-pole

15 m

* For use in the operating mode Restart Interlock (manual reset)

Adapter cable for parameter setting

Item N

o

Designation Description

Length

103013625 KA-0977

Pushbutton with

command device

1x male connector M12, 5-pole

2x female connector M12, 5-pole

3 m

Electric heater (only SLB450-ER-x-ST-EH)

Recommended wiring for SLB450 with electric heater:

• Max cable length: 20 m

• Cable cross section up to 25 m: 15 mm² -

installation with +24V and 0V

• Cable cross section 25 m to 75 m: 2 x 15 mm² / 1 x 40 mm² -

installation with +24V and 0V

At larger distances (>15 m), it is recommended to supply both sensors

of the AOPD with separate power supplies to keep the cable lengths

short

Following installation, the operating voltage must be measured at

the last terminal to the heater If the operating voltage is outside the

specification, this is indicated by a "flashing white" status signal In this

case, the operating voltage must be adjusted

Power supply is to be dimensioned with sufficient reserve and should

have a capacity of 3 A per device or 4 A for both