6

Operating instructions

Safety light barriers

SLB440

SLB450

EN

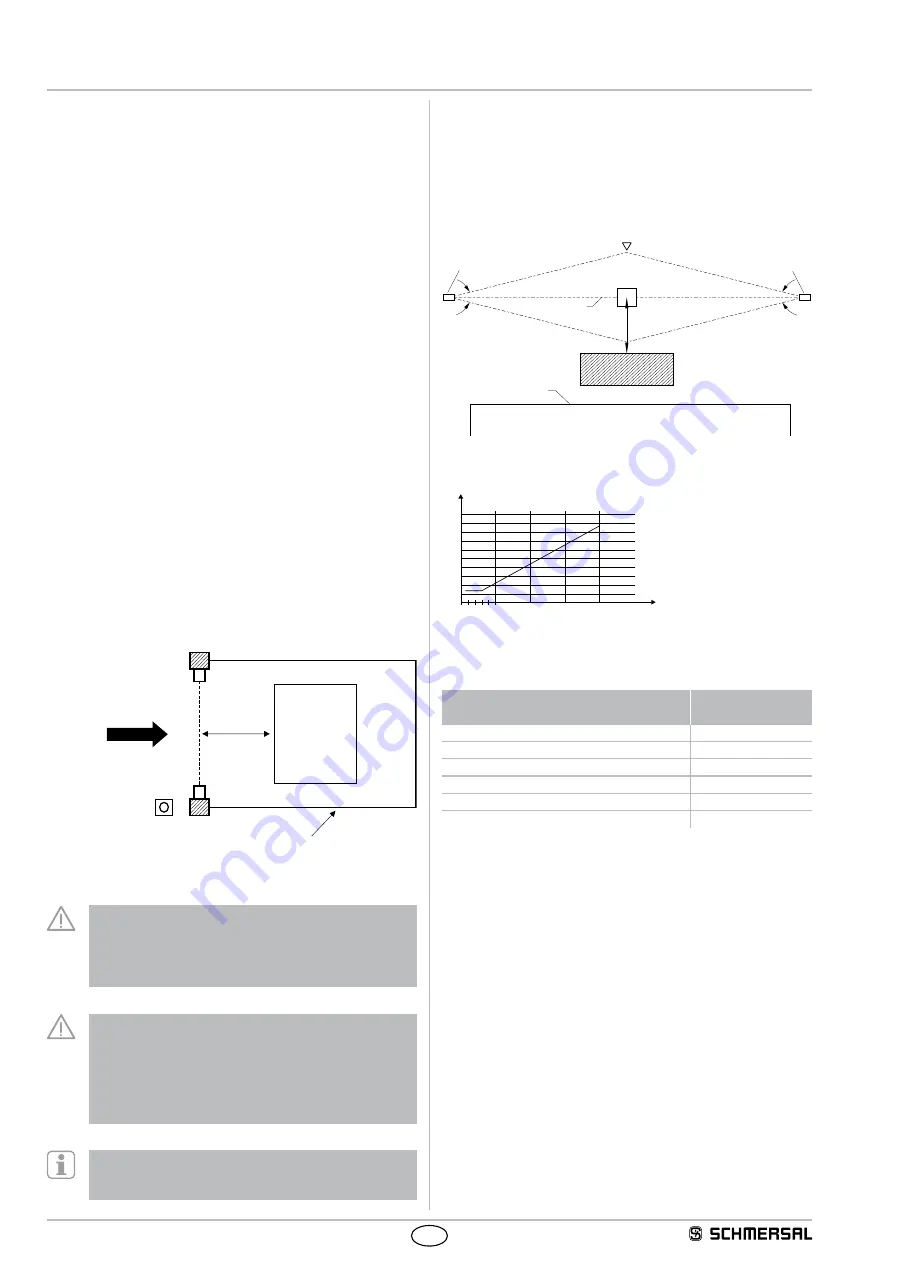

3.5 Safety distance

The safety distance is the minimum distance between the protection

field of the safety light barrier and the hazardous area The safety

distance must be observed to ensure that the hazardous area cannot

be reached before the hazardous movement has come to standstill

Calculation of the safety distance to EN ISO 13855 and EN ISO 13857

The safety distance depends on the following elements:

• Stopping time of the machine (calculation by run-on time

measurement)

• Response time of the machine and the safety light barrier and the

downstream safety-monitoring module (entire safety guard)

• Approach speed

Safety light barrier

The safety distance for the safety light barrier is calculated by means of

the following formula:

S = (1600 mm/s x T)+ 1200 [mm]

S = Safety distance [mm]

T = Total reaction time (machine run-on time,

reaction time of the safety guard, relays, etc)

To prevent the AOPD from reaching over or creeping under, the beam

should be installed 750 mm above the ground or reference level

(see ISO 13857)

If using safety light barriers, the following points must be observed:

• Prevent the possibility of going under or over the beam

• Prevent the possibility of reaching through between two beams

• Prevent the possibility of climbing through between two beams

Safety distance to the hazardous area

S

Hazardous

point

Transmitter

Receiver

Command device

Authorised operation

Mechanical protection

Direction from which the

hazardous area is accessed

Please observe the applicable harmonised EN standards and possible

applicable national regulations

The safety distance between the safety light barrier and the

hazardous point must always be respected and observed If

a person reaches the hazardous point before the hazardous

movement has come to a standstill, he or she is exposed to

serious injuries

The AOPD should be located parallel with the floor and the

beam should be interrupted by the upright body of a person

A single beam AOPD as the only guard system is not suitable

for preventing the whole body of a person from accessing

We recommend combining the AOPD with other protective

equipment to make it impossible to pass by the guard system

without being detected in the process

To calculate the minimum distances of the safety guards

with regards to the hazardous point, the EN ISO 13855 and

EN ISO 13857 must be observed

3.5.1 Minimum distance to reflecting surfaces

During the installation, the effects of reflecting surfaces must be taken

into account In case of an incorrect installation, interruptions of the

protection field could possibly not be detected, which could lead to

serious injuries The hereafter-specified minimum distances with regard

to reflecting surfaces (metal walls, floors, ceilings or parts) must be

imperatively observed

8°

8°

a= 262 mm

Access direction

Receiver

Obstacle

Optical axis

Transmitter

Reflecting body

(eg Material container)

Limit of the

hazardous point

a=130mm

5°

5°

Safety distance a

a [mm]

D [m]

0

3 5

10

100

200

300

400

500

600

700

800

900

1000

15

20

Calculate the minimum distance to reflecting surfaces as a function of

the distance with an aperture angles of ± 2.5° degrees or use the value

from the table below:

Distance between transmitter and receiver

[m]

Minimum distance

a [mm]

02 … 30

130

4

175

5

220

7

310

10

440

12

530

Formula: a = tan 2.5° x L [mm]

a = Minimum distance to reflecting surfaces

L = Distance between transmitter and receiver