10

EN

SLC 430

Operating instructions

Safety light curtain

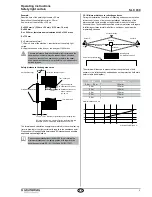

6.3 Fault diagnostic

Failure/malfunction

Possible causes

Check and elimination

Although being clear, the protec-

tion field is not enabled after the

actuation of the command device,

indicator lamp green

No contact of the wiring from the output relay to the

machine control

Check terminals and re-wire if necessary

Defective fuse in output relay

Check fuse F5/F6

Although being clear, the protec-

tion field is not enabled after the

actuation of the command device,

indicator lamp red

Both or one of the sensors incorrectly wired to the

safety-monitoring module

Check polarity and bus connection of the terminals

Translucent surface of the sensors highly soiled

Clean surface

Malfunction of one or more beams

Contact the customer service department

Although being clear, the protection

field is not enabled after the actu-

ation of the command device, no

indication from indicator lamp

Safety-monitoring module's supply voltage missing

Check terminals and re-wire if necessary

Malfunction of the fuse of the supply voltage input

Check fuse F1

Protection field clear, but no enabling

Normal operation - LED 5 (red) emits every 3 seconds the following flash impulses

Permanent flashing

Synchronisation error

Exchange safety-monitoring module

1 flash

Error self-test

Exchange safety-monitoring module

2 flashes

Communication error

Exchange sensor pair, check cable pair

3 flashes

Communication Sensor E

Check cable E, exchange sensor pair

4 flashes

Communication Sensor R

Check cable R, exchange sensor pair

5 flashes

False plant parameters

Check plant components assignment

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised condi-

tion only.

7.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.

8. Appendix

8.1 Contact

Consultancy / Sales:

K.A. Schmersal GmbH

Industrielle Sicherheitsschaltsysteme

Möddinghofe 30

D-42279 Wuppertal

Tel:+49 (0) 202 64 74 -0

Fax:+49 (0) 202 64 74- 100

You will also find detailed information regarding our product variety on

our website: www. schmersal.com

Repair handling / shipping:

Safety Control GmbH

Am Industriepark 11

D-84453 Mühldorf / Inn

Tel.: +49 (0) 8631-18796-0

Fax: +49 (0) 8631-18796-1